- Design code: ASCE

- Design life:50 years

- Dimension: Φ10.4*5

- prefab structure with full bolting

- Roofing: 5(blue tempered glass)+ 5(clear tempered glass)+12A(structural adhesive)+ 5(clear tempered glass)+5(clear tempered glass)

Your current browser version is too low, in order to bring you a better browsing effect, please use a higher version browser

Product Category

Product Category

(1)The glass dome building shape is high on visual impact and in most cases is both strong and durable. Domes roofs are used for providing maximum daylight on flat roofs. They are the ideal solution when conventional windows and roof windows cannot provide adequate daylight or ventilation. Manufactured in virtually indestructible double (or treble) skinned polycarbonate, The glass dome roof is available in a wide range of sizes.

(2)The glass roof domes are available in square, rectangular, and circular shapes, with opening, access, and ventilating options. They are installed using pre-formed flashings, or glass, which combines with existing roof coverings.

(3)The glass dome roof steel structure, including the main steel beam and secondary steel beam, as the main beam is connected with the ring one end of the main beam, the other end is connected with the embedded parts; Steel beam as the parallel to the side of the main steel beam connection, form a dome structure, the bottom of the main beam welding plate, through bolt hole is set up in the floor I fixed on the embedded parts, the other end of the welding connection plate, connection plate with bolt holes, along the length direction of the main girder, the steel beam connections with the time of the joint of the two sides of the same height, symmetrical opening bolt hole I, Every two pairs for a group, spacing layout; Time at both ends of the beam welding connection plate, connecting plate and the main girder of bolt hole I corresponds to the set screw hole II, benxi steel structure will just receive node bolt, can improve the construction speed, avoid welding operation, reduce the possibility of a fire, and there is no welding deformation, steel and glass dome synchronous processing production, the dome can be put into use sooner.

(4)More recently, the glass dome building roof light is designed to maximize the amount of natural daylight in a building and at the same time provide a clean minimalistic finish both inside and outside. We are manufactured with dome glass roof units and incorporate a fully welded steel frame.

LF offers a good option in glass dome roofs, which are marketed as quick construction, low cost, energy-efficient, space utilizing, durable, weather-resistant storage, and the public using buildings. Which is also favored by those seeking alternative, energy-efficient, and windproof buildings.

|

Structure Type: Light Steel |

|

Application: Glass Dome Roof |

|

Design Standard: ASCE |

|

Span: 10.78m |

|

Height: 10.78m |

|

Wind Zone: 35m/s |

|

Seismic Zone: 4(Z=0.4) |

|

Certificates: ISO, CE, SGS |

|

Steel Material: A36/ ASTM |

|

Surface Treatment: Epoxy Zinc-rich primer and PU finish paint |

|

Roof : 5+5+12A+5+5 hollow laminated tempered glassd |

|

Dimension: Φ10.4*5 |

|

Shipping: 45 working days after designing drawings are confirmed with a signature |

|

Installation: Supervision by LF engineers |

|

Packaging Details: Special export packing for BJMB materials |

|

Design life:50 years |

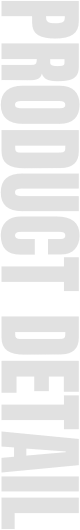

The steps of installation of glass dome roof building are as follows: measuring and laying out → adding steel structure welding → purlin support → installation of T-shaped aluminum connecting piece → installation of the main keel of lighting top → installation of the secondary keel of lighting top → installation of sealant pad → installation of glass panel → rubber sealing.

Glass Dome Roof Installation Steps