Solution

SolutionGas stations are an essential part of modern life, and their design and function continue to evolve to keep up with changing customer needs. One important aspect of gas station design is the canopy that covers the fueling area. Steel structures are a popular choice for gas station canopies due to their strength, durability, and versatility.

Engineering characteristics

1. The quantity of each gas station canopy project is small, but the requirements are relatively professional, so multiple copies can be made. At the same time, the cost is very high due to the small volume when single design, production, and installation.

2. Welding should be avoided at the site, especially in the operation of the gas station, and should avoid open fire, so once built, it should continue to be used as far as possible without maintenance (to avoid sparks).

3. Install as quickly as possible and put it into use soon.

4. Outdoor gas stations should be protected from lightning and wind as far as possible.

5. The canopy of the gas station should preferably be in the form of a light steel structure and adopt a safe and reliable steel structure

Application area

1. space frame structure for gas/petro/fuel/filling station

2. space frame structure for natural gas station

3. flat space frame structure

Solutions

The gas station project is divided into the new gas station project and the reconstruction and expansion of the gas station project. New gas tanks commonly do not reach the designated position, with no fire danger, so the h-beam structure can be used. It’s a kind of structure form that is a big welding workload. For the reconstruction of the gas station, short construction time, small construction site, has certain fire danger, all bolt connection of steel structure and spatial structure is more applicable, effectively avoiding a large amount of site welding, avoid fire danger. Steel is an alloy of iron and carbon that can contain up to 2% carbon. It is the most widely used material in building infrastructure and industries around the world. Steel has a high tensile strength, which means it can resist large forces without breaking or deforming. In addition, steel can be fabricated into different shapes and sizes, making it a versatile material for various construction applications.

1. Due to the single volume, it is small, and high cost, and because the BJMB way installs quickly, it can carry on the mass design, manufacture, and installation.

2. Site installation does not require welding, but it is safer for gas stations in operation (it should also be closed in case of emergency).

3. The installation and lifting of the BJMB structure are very fast. The installation of the main structure of the general gas station only needs 2~5 days (the area and the structure form are determined) to be able to be fully hoisted into place and transferred to the roof installation.

4. Metal roof lightning protection is better, BJMB space frame roof structure is designed through wind-resistant.

5. The filling station canopy produced by LF has good seismic performance, high rigidity, good integrity, small steel consumption, can effectively withstand dynamic loads, standardized components, is easy to manufacture and install, flexible layout, and a beautiful appearance

Process description

Design process: The space frame structure of toll station BJMB is subjected to various loads, and the biggest damage may be the large wind load, which will produce the overall upward lift. Therefore, the z-direction stress should be paid attention to in the design. It is necessary to carry out the calculation of hoisting, to prevent hoisting danger when designing.

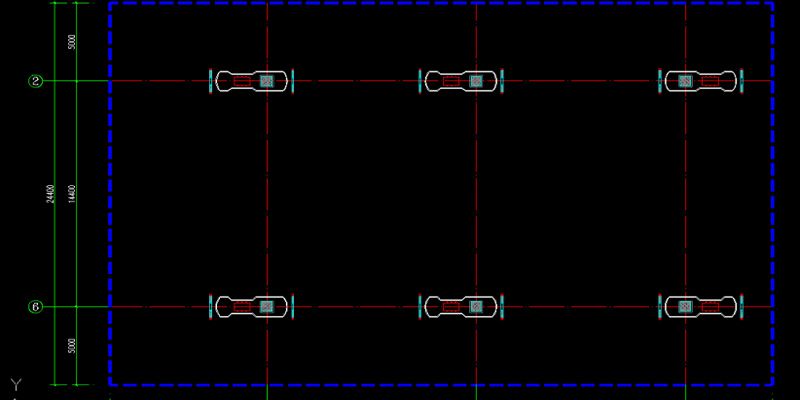

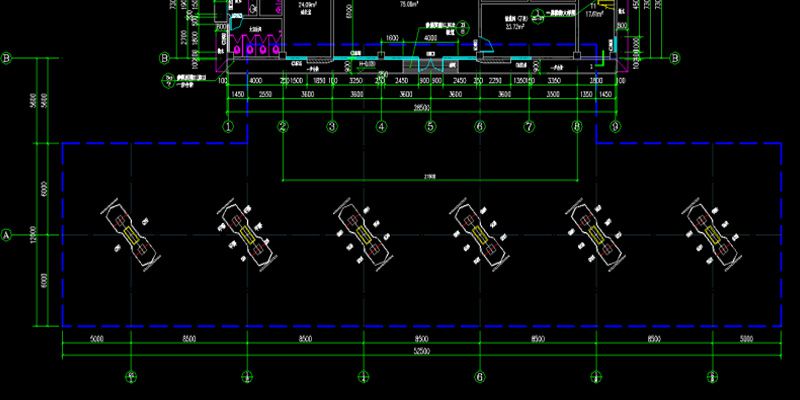

The design forms of fuel station canopies have also become diverse. The first is a single-row column canopy (as shown in Figure 1-1), the second is a multi-row column canopy (as shown in Figure 1-2), and the third is built on The canopy on the corbel of the standing pillar (as shown in Figure 1-3)

Figure 1-2multi-row-column canopy

Figure 1-3 The canopy on the corbel of the standing pillar

Production process: all components are produced in the factory, especially welding, and only need to be bolted according to the number on site.

Installation process: generally, the bolts installed for structures on the ground, are safe and reliable. After the installation is completed, the whole structure is lifted (except the plate, which must be installed in the air). The lifting point must be checked.