Reinforcement methods:

1. Change the structural calculation sketch: change the load distribution, force transmission paths, node properties, boundary conditions, additional bars, and supports, applying to prestress, consideration of spatial synergy, etc.

2 No change in the structural calculation sketch: reinforcement of the cross-section and connection of members (increased cross-section method)

3. Unloading reinforcement: serious damage to members or joints with high stress, reinforcement construction must be.

4. Not unloading reinforcement: the original structure should be not less than 20% of the surplus, the thickness of the weld is increased, and the original weld in the deduction of the length of the welded residual heat-affected zone of the bearing capacity should be not less than the external load generated by the internal force.

There are many kinds of steel structure reinforcement methods, this paper focuses on changing the structural calculation sketch and not changing the structural calculation sketch.

Changing the calculation sketch

a.Change the moment graph of the member

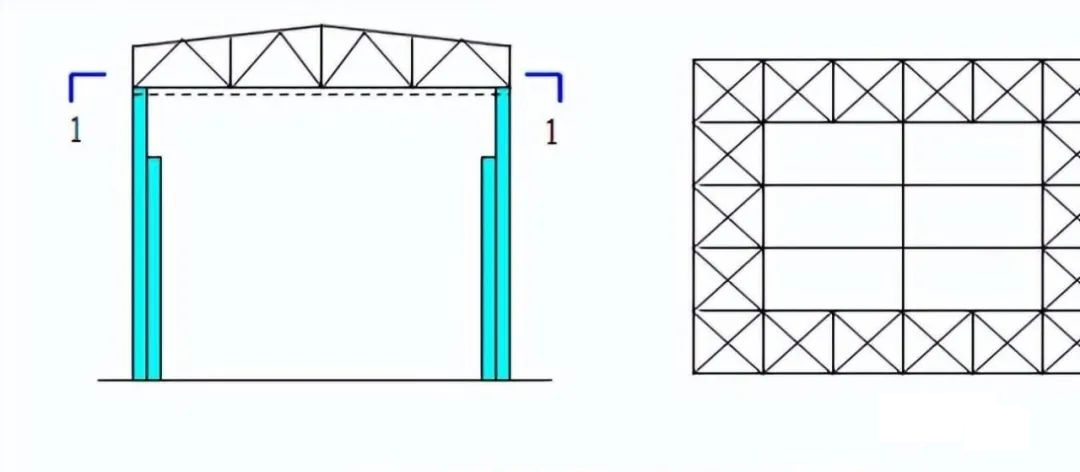

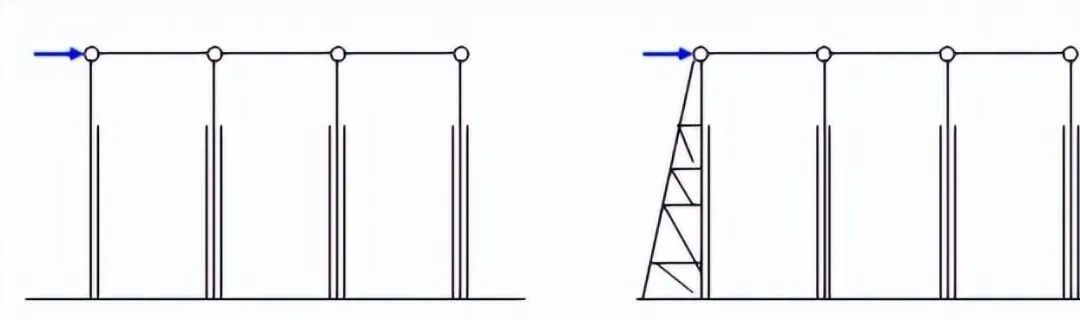

1. Increase the roof support to the structural space stiffness so that the row of columns can be calculated according to the space structure, to explore the potential of the structure.

Adding roof supports for structural spatial stiffness

2. Additional bracing is provided to adjust the self-oscillation frequency of the structure and improve the dynamic performance of the structure.

Increased support

3. Additional bracing is provided to reduce the length-to-slender ratio of the member and improve stability.

Increased support

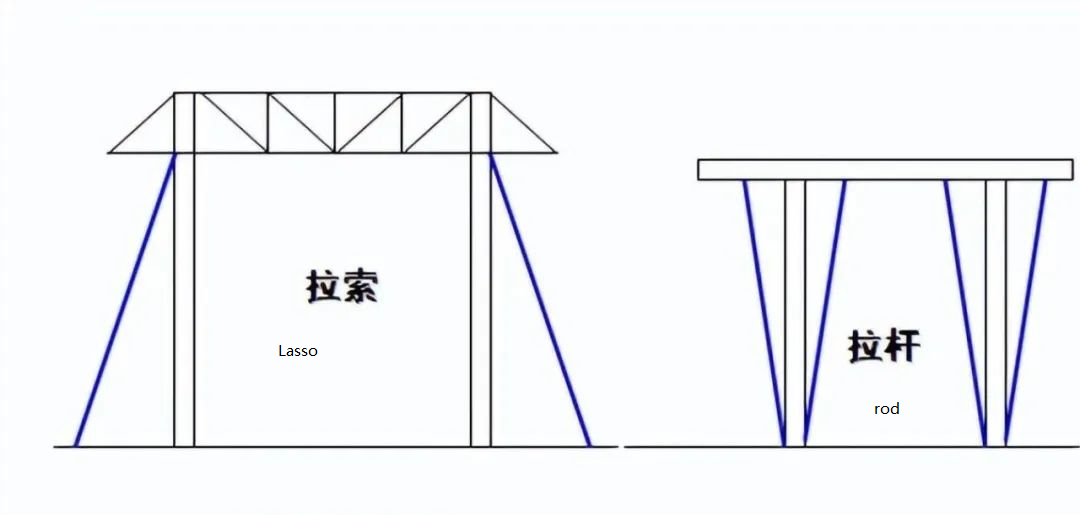

4. Provide tie rods or moderately tensioned cables in structures such as towers to strengthen the rigidity of the structure.

Adding cables or rods

b.Changing the bending moment pattern of a member

1. change the distribution of loads, change the centralized loads to multiple centralized loads;

2. change the end support situation, such as articulation and rigid connection;

3. Increase the intermediate support and change the simple support to continuous;

4. adjusting the position of the structural support and changing the structural span; and

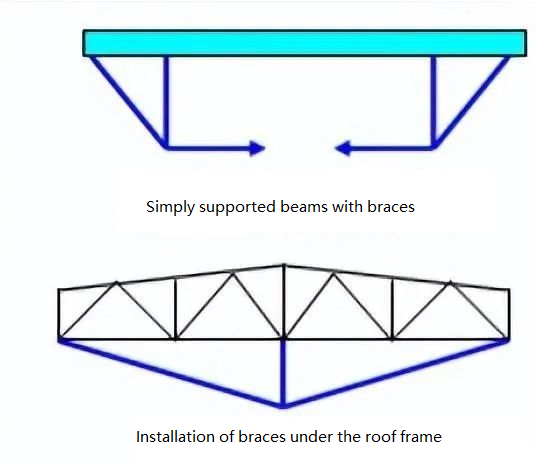

5. changing the member to a braced structure; and

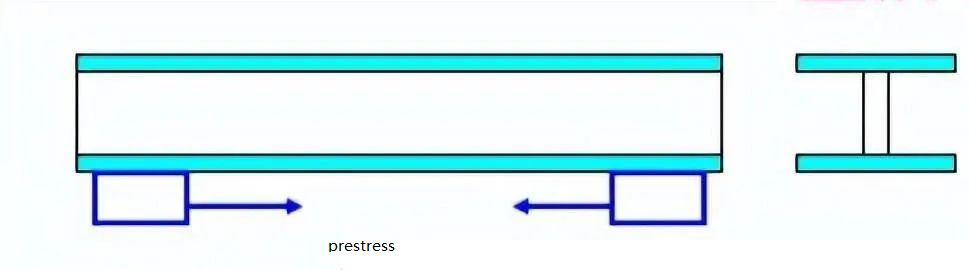

6. applying prestressing

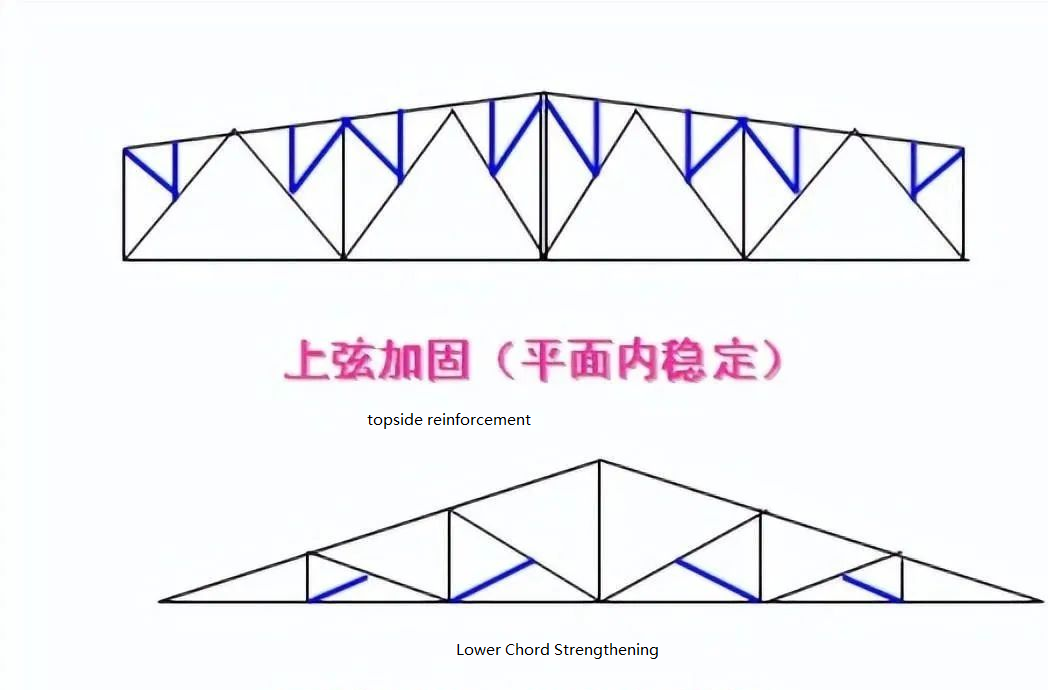

c.Changing internal forces in truss members

1. Addition of spacers to transform the truss into a spacer-type structure.

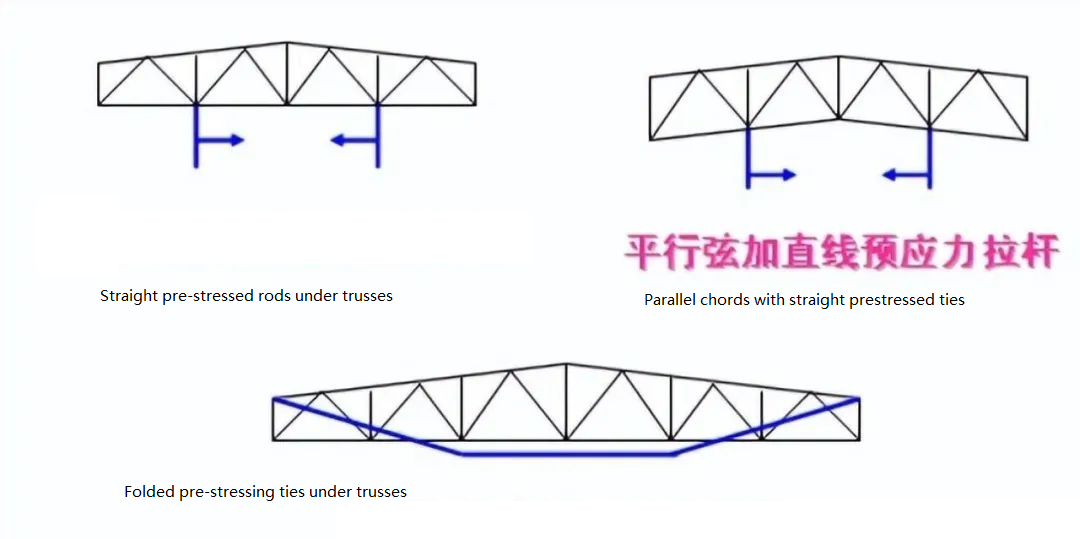

2. Add pre-stressing tie rods

d.Improvement of stress conditions

1. Strengthen the nodes and increase the support, so that the steel roof frame and skylight frame work together.

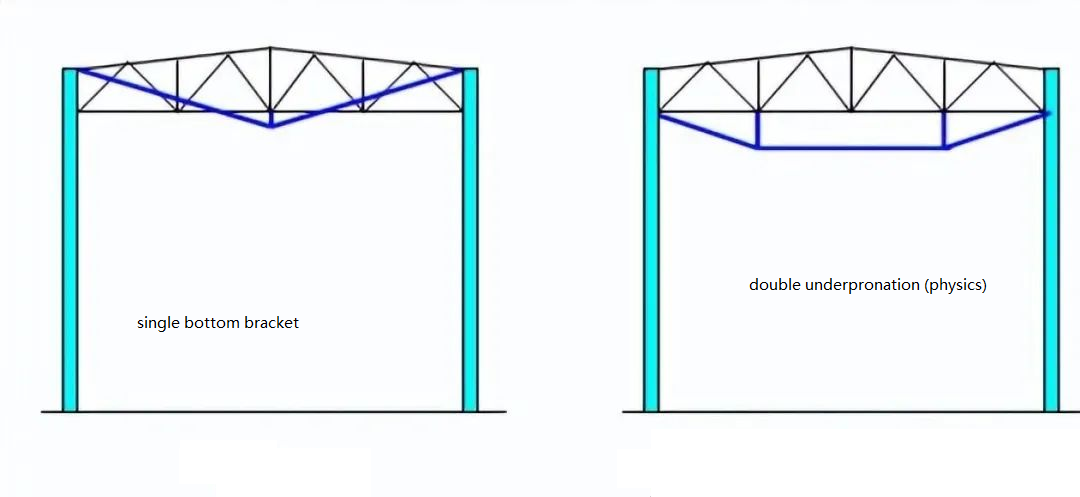

2. Rows and frames, to reduce the reinforcement workload and the impact of reinforcement construction, focus on strengthening a column column stiffness, other column columns can not be reinforced or small reinforcement.

Increase the cross-section of the member

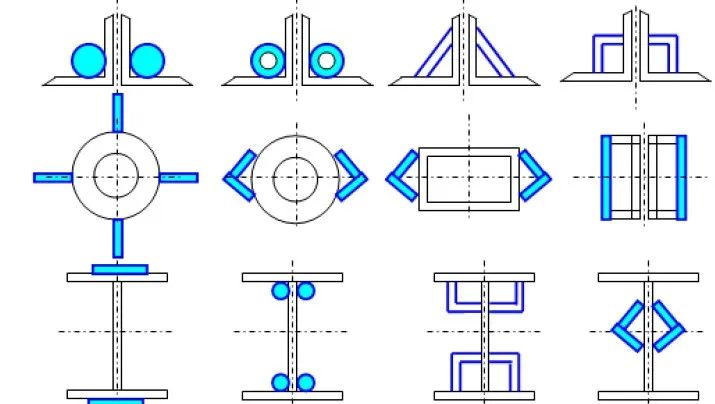

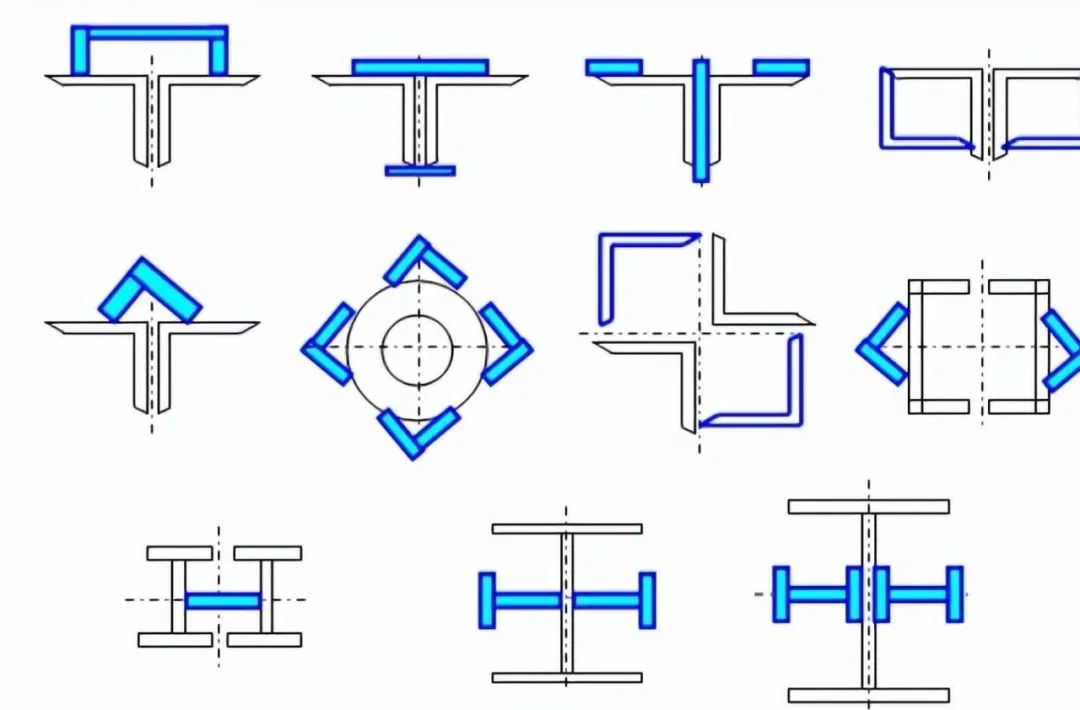

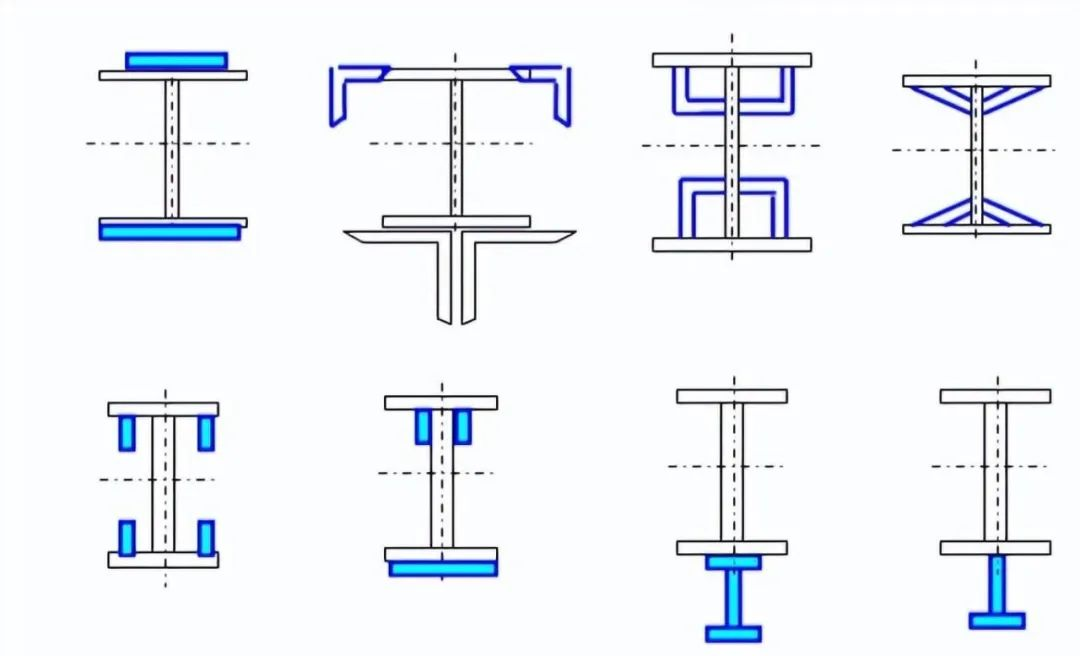

a.Changing the form of reinforcement in the cross-section of a member

b.Factors considered in the increased cross-section method

1. Ensure that the reinforcing elements have reasonable force transmission paths and that they work together with the original elements.

Reinforcement elements should be arranged in such a way that they can be adapted to the geometry or deformation of the original element to facilitate construction.

2. Minimize the amount of reinforcement work (use welding as much as possible).

3. When welding is used, the amount of welding work should be minimized, attention should be paid to the welding sequence, welding deformation and stress should be reduced, and back welding should be avoided. In the load state welding should be used smaller welding size, and should be the first reinforcement of the original components to have less impact on the weakest parts of the components, etc.; 5 light steel structure in the small angle of the structure.

4. light steel structures in the small angle and round steel rod should not be welded under load, if necessary, appropriate measures should be taken, round steel is strictly prohibited under load welding.

5. Increasing the cross-section size can not be too much to weaken the original member of the bearing capacity, try to use small bolts and high-strength bolts, welding should try to avoid the use of the original member of the stress direction perpendicular to the weld. Otherwise, special measures should be taken.

About Us

About Us 2024-05-13

2024-05-13