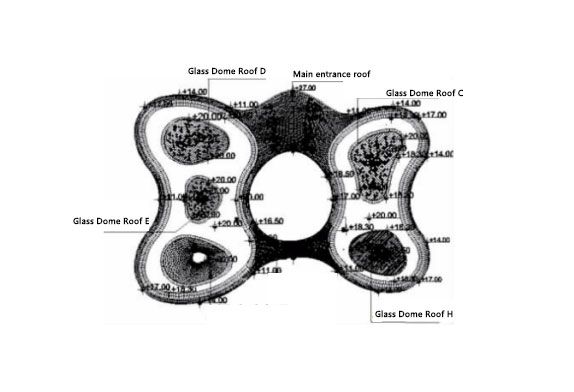

FIG1.Glass Dome Roof in International Shopping Mall

With the continuous development of architectural technology and the diversification of architectural effect requirements, the application of glass dome roofs is more and more widely, and its design form is more and more novel, but it also brings great difficulties to the design and use of dome glass roof safety. Taking the international shopping mall as a case, this paper introduces the waterproof design scheme of the hyperboloid glass dome building roof.

1. Glass Dome Building Roof Project Overview

The international shopping mall project is divided into two phases, the first phase is a shopping center, and the second phase is a hotel and villa, with a total investment of 5 billion yuan. The total area of the project is about 190,000 m². The total construction area of the shopping center is about 123098m², including three floors above ground, about 66,589 m². 1 floor underground, about 56,508 m², is one of the largest single duty-free shopping malls in the world.

The overall shape of the project is butterfly-shaped, with the main entrance on the north side, the corridor on the south side, and the large free-body roof connecting the two buildings to form an organic whole (Figure 1). The interior space of the building is guided in series by four themed atriums and sunken lighting well. The glass lighting roof of the atrium is made of glazed glass and ordinary glass according to the lighting characteristics and cleverly introduces natural elements to provide customers with bright light sources unique to Hainan. The funnel lighting roof is designed with tropical green plants and water features, providing a place for customers to relax and enhance the commercial value of the overall space.

2 The detailed layout of the glass skylight roof system of the International Shopping Center is shown in Figure 2. The whole roof system consists of the main entrance roof, corridor, D, E, H, G lighting dome, and funnel lighting roof, covering an area of about 25000m2. The main entrance roof and corridor are open roof, while the lighting dome and funnel lighting roofs are closed roofs, which is the key and difficult points of the waterproof design.

FIG. 2 Distribution of glass roof system

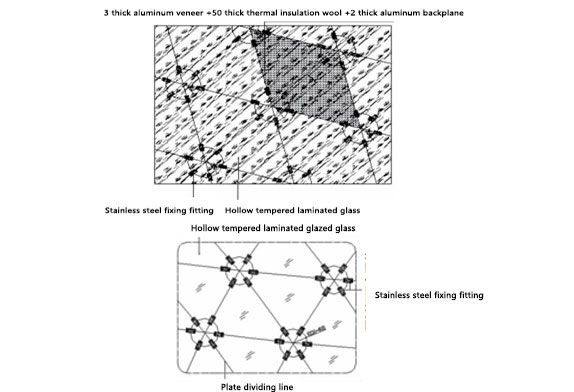

Both the lighting dome and the funnel lighting roof are non-developable surfaces, and their panels are difficult to be divided regularly. If the panel partition is too large, it is difficult to meet the curvature requirements of the surface; And the use of quadrilateral partition, there may be 4 points that are not coplanar, adjacent plates are interlaced, there will be uneven joints, increasing the probability of leakage. If the panel partition is too small, it will increase the profile rod, affecting the visual effect. Finally, the lighting roof of this project adopts a larger plate triangular partition design. According to the lighting characteristics, the glass is composed of 8+12A+8+1.52PVB+8 double silver low-E hollow toughened laminated glazed glass and 10+12A+8+1.52PVB+8 double silver low-E hollow toughened laminated glass. The irregular 3mm thick fluorocarbon spraying monolayer aluminum plate is set locally, and the inner lining is 50mm thick thermal insulation rock wool +2mm thick aluminum alloy backplane, which not only ensures smooth surface changes and neat joint splicing but also subtly forms a decorative effect of blue sky and white clouds. But because the panel uses triangular plates, six plates meet at one point; The maximum span of the lighting dome is 36m, the highest elevation is 25.534m, and the lowest elevation is 18.8m; The maximum span of the funnel lighting roof is 28.880m, the highest elevation is 20.000m, and the lowest elevation is -0.4mm), which brings more difficulties to the flatness and straightness of the intersection point which are already difficult to control, and increases the probability of leakage

FIG.3 Partial size of the skylight dome AND A partial sample of funnel skylight roof

3 Waterproof design of the glass roof

The waterproof design of the dome roof follows the principle of “ensuring function, reasonable structure, a combination of prevention and drainage, and selection of materials”. The comprehensive use of measures such as “guide” and “blocking” is adopted. On the one hand, the slope of the lighting roof system is used to quickly drain rainwater. On the other hand, the gap between glass panels is blocked by a weather-resistant sealant.

3.1 Reasonable drainage design

The roof of this dome roof project is a spacious roof with large fluctuation. The drainage slope of the roof itself is large (the minimum drainage slope of the top edge of the lighting is set at 3%), and the surrounding area is relatively low. The water is discharged to the surrounding area of the roof under the action of gravity. A drainage ditch is also set at the bottom of the funnel lighting roof to drain the water from the funnel lighting glass dome roof. During the specific operation, in order to ensure that the roof catchment is discharged at the fastest speed, the drainage area of the roof should be divided according to the principle of “shortest distance, the most effective, and the clearest”.

3.2 Waterproof and sealing design

This dome glass roof project a waterproof seal on the top of the daylighting glass dome building design mainly joint seal between the glass plates, selection of materials for silicone with 25 level displacement ability weathering sealant, joint width is 16 mm, selection principle is: ensure the sealant are in a state of tension or compression, remained intact, bonding and has good elasticity.

For the most prone to leakage of stainless steel fixed accessories, first in the lower layer of waterproof gasket for strengthening treatment, and then around the use of silicone weather-resistant sealant seal.

3.3 Waterproof design for opening skylight Funnel lighting top is provided with an opening skylight, which is arranged intermittently.

Its waterproof structure is made by setting a batch water plate to keep water away from the waterproof node; At the same time, raising the opening fan, making it 130mm higher than the glass surface, and increasing the sealing fortification channels, improving the waterproof performance.

4 Construction points

In order to ensure the waterproof effect of the dome glass roof, in addition to reasonable drainage design, but also strict control of the site construction quality.

The roof system adopts a single-layer reticulated shell support structure. The glass panels are directly fixed on the single-layer reticulated shell structure through a point-fixing system. All the load of the panels is transferred to the supporting structure through each fulcrum. The stainless steel base of the point fixing system is provided with long holes in the left and right directions to achieve adjustable installation errors in the left and right directions; The base itself can be moved forward and backward on the rod of the mesh shell structure to adjust the installation error in the forward and backward directions; At the same time, through the screw thread between the base and the glass fixture, the installation error adjustment in the high and low direction is realized, so as to ensure the three-dimensional installation and adjustment between the glass panel and the reticulated shell structure, so as to ensure the flatness of the whole roof system. At the same time, the stainless steel connector and the glass panel contact part adopt the ball hinge structure, the ball hinge center is in the center of the glass, the round gasket made of nylon is added between the ball head and the glass, which can make the glass produce free deformation, and can achieve ±10° Angle adjustment, which is conducive to the glass force; Spherical connection is also used between the ball head and the pressure plate, and the ball head is connected to the upper and lower pressure plate by special screws, which not only ensures the flexible rotation of the ball head but also connects to the whole. This kind of floating connection can meet the requirements of all kinds of deformation of curtain walls, and effectively avoid the damage to glass panels caused by structural deformation.

4.2 Installation of the Lighting glass dome roof system

When installing the lighting dome and funnel lighting roof, it should be noted that the laminated layer of insulating glass should be placed on the lower surface. Even if the laminated glass is broken, glass fragment rain will not be formed.

4.3 Construction glue injection for joint sealing should not be carried out on rainy days.

The glue injection surface should be clean and free from water, oil stains, rust, mortar, and dust, etc. After purifying the injection surface, the injection should be carried out within 10~15min. The glue joint requires a smooth appearance, no distortion, no cracks, no impurities, no obvious defects, and no three surface bonding phenomenon.

5 conclusion

International shopping center hyperboloid glass dome shape roofing system USES a space, and the larger the change of curvature of the surface, when the design panel using the triangle frame design, large plate glass according to the characteristics of colored glaze glass and common glass daylighting, a partial set of irregular single-layer aluminum plate, can not only ensure the surface is smoother and changing seam joining together more tidy, Can form the adornment effect of a kind of blue sky, white cloud skillfully again. The waterproof design of the project follows the principle of “ensuring function, reasonable structure, a combination of prevention and drainage, and optimization of materials”. On the one hand, the slope of the lighting roof system is used to remove rain quickly; On the other hand, the gap between the glass panels was sealed by the weather-resistant sealant, and a better waterproof effect was achieved.

About Us

About Us 2022-09-07

2022-09-07