Since the 20th century, the space structure has been greatly developed due to its unique advantages. As a kind of space structure, the space frame structure is favored by people for its high-efficiency mechanical performance, simple construction and production, and flexible and diverse shapes. Since the space frame structure was introduced into our country in the 1960s, it has developed rapidly. The space frame structure is generally divided into welded ball joint space frame, bolted ball joint space frame and plate joint space frame, among which the bolt ball space frame is the most widely used. Let’s take a look at the manufacturing process of bolt balls.

1、Introduction of bolt ball processing machine tools

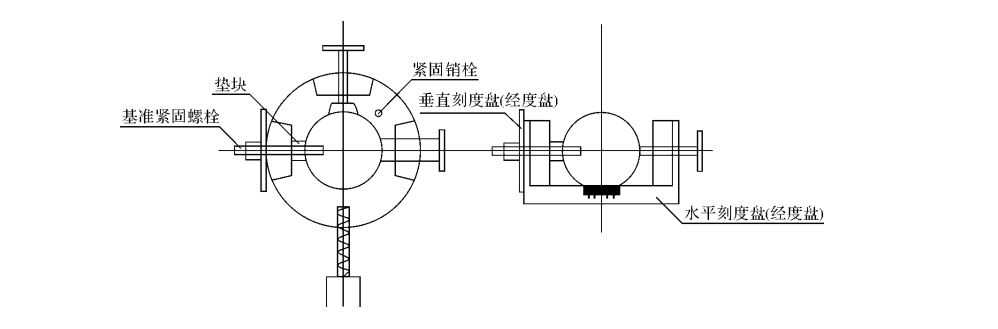

As shown in Figure 1, the bolt ball is fixed on the machine tool with the reference fastening bolt after the reference hole is made. The reference fastening bolt, the center of the ball and the tap are located on the same horizontal plane, and the size of the spacer is used to switch bolt balls of different diameters, so that It is ensured that the taps pass through the center of the ball when they are tapped. The latitude and longitude control during bolt ball processing is mainly realized by the vertical dial and the horizontal dial. The vertical dial is used to control the longitude of the ball, and the horizontal dial is used to control the latitude of the ball. The minimum scale values of the two dials are degrees, and the fastening pin is used to fix the horizontal dial. In addition, the chuck device of the entire bolt ball can slide along the axis direction of the tap, and the minimum scale of the sliding distance control dial is millimeters.

FIG. 1 Schematic diagram of bolt-ball machining machine

2、Bolt ball processing and production process

Make the datum hole – select the cushion block according to the ball diameter – fix it on the machine tool with the reference fastening bolt – adjust the horizontal dial and vertical dial to make the end plane – adjust the horizontal dial and vertical dial again to make the screw hole – processing quality inspection – brush Paint, number.

3、Industry Standards for Bolt Ball Processing and Manufacturing

The state specification for the space frame stipulates that the cutting amount of the plane of the bolt ball end must ensure the pressure bearing surface of the sleeve, and the screwing depth of the bolt is 1.1 times the diameter of the bolt. Considering the poor controllability of the actual machining accuracy, the effective depth of the screw hole is generally 1.2 times the diameter of the bolt.

About Us

About Us 2024-08-30

2024-08-30