1、Project Overview

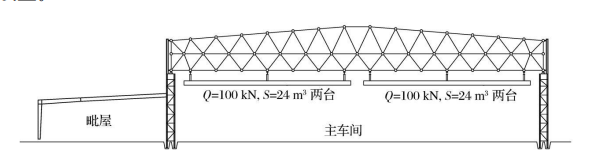

Production workshop project of Ende (Dongying) Wind Power Equipment Co., LTD., with a total planning of 25000m2, this construction is the first phase project, including the main production workshop, attached pili house and office building three parts, with a total construction area of 12000m2. Main workshop plane size 140m*60m, span 60m. Four 24m span three-rail suspension cranes are set up in the workshop, in pairs and side by side.

Workshop cross-section drawing

The longitudinal spacing of the steel columns in the main workshop is 14m, and the steel lattice columns are used. Post built adjacent house span 20m, door type light steel structure, workshop roof using three welded ball space frame structure. The office building is a three-storey concrete frame structure. The project investors on the project cost and project time requirements are very strict, and strive to structure design not adhere to traditional ideas, a breakthrough and innovation.

2、Structural characteristics and main design requirements

This engineering structure has two major design difficulties: one is the structure span is large. Since the single length of the wind turbine blade planned for production in the workshop is about 30m, according to the requirements of the flow operation, no column is allowed in the middle of the 60m span. Second, the load is heavy and the deformation is strict. Four three-rail cranes with a lifting weight of 100kN and a span of 24m should be suspended on the roof. In order to ensure the normal operation of the crane, the structural deformation must be strictly controlled.

Main design parameters: the safety level of the production workshop, the attached building adjacent to the house and the office building structure is level two, and the design service life is 50 years. The basic seismic intensity of the site is 7 degrees (0.15g), the design earthquake group is the second group, the site category is class 1, and the seismic fortification classification is Class C. Basic wind pressure 0.60kN/m2, ground roughness class A, basic snow pressure 0.3kN/m2.

The main design load of the structure, in addition to dead load, live load, wind load, snow load and temperature load, etc., the roof is suspended by 4 cranes with a lifting weight of 100kN, and the total weight of the suspension load is about 1000kN.

The design of the large span plant should first meet the functional requirements, and also consider the coordination with the surrounding building environment. Therefore, to meet the use and aesthetic requirements, safe and reliable, economical and reasonable is the goal of structural design.

3、Structural scheme selection and optimization adjustment

3.1、Primary selection of roof scheme

According to the requirements and characteristics of the project, in the scheme design stage, the comparison of the space frame, space frame shell, truss and portal frame structure forms. Due to the large span and the suspension crane, the possibility of implementation of the portal rigid frame is very small. Considering that truss structure is used more in similar factories in Europe, its advantages lie in plane force transmission, lower requirements for the lower structure, simple production and installation, better visual effect, simple structure form, but the overall stiffness of truss roof is poor, and more support systems need to be arranged. Under the same load condition, the truss structure will use a high amount of steel to ensure sufficient stiffness. Mesh shell structure stiffness, beautiful shape, due to its space force characteristics, direct force transmission, for the three-dimensional force, large stiffness, good seismic performance, convenient construction and installation, product production standardization, quality and construction schedule is easy to ensure, and easy to hang crane, heating and spraying system and other pipelines. Through the analysis and comparison of all aspects, the roof selected space frame scheme.

3.2、Optimization of space frame scheme

The space frame structure is usually divided into two types: bolted ball space frame and welded ball space frame. The bolt ball space frame has low cost, complete products, fast construction and installation speed, easy to control accuracy, and is the preferred space frame structure form. Its limitation is limited by the size of the bolt, the internal force of the rod generally can not exceed 1000kN, and is only suitable for small and medium-sized span structures. Although the welded ball space frame cost is relatively high, but the overall stiffness and joint stiffness are better than the bolt ball space frame, the peak internal force of the rod is greatly increased, can be used for large span structure, and can bear large joint load, hanging joint structure is easy to handle. According to the span and suspension of this project, the fully welded ball joint space frame is selected.

About Us

About Us 2024-09-09

2024-09-09