1. Steel Stadium Project Overview

The Football Stadium (Figure 1) has a total construction area of 52,795m2, and the number of spectator seats is 34,318 (including 30,694 fixed stands and 3,624 active stands). The roof has a unique shape, in the shape of a saddle that is high from east to west and low from north to south. In addition to the undulating changes in the elevation, the plane projection size also changes significantly; the lower north-south roof has smaller overhangs, and the higher east-west overhangs are larger. The lower stand of the stadium adopts a reinforced concrete frame structure, and the upper roof adopts a stadium roof truss design.

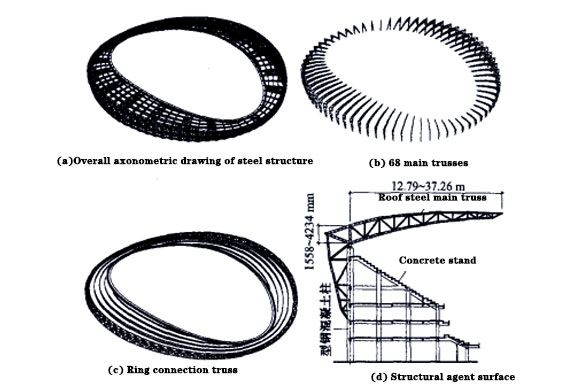

Fig.1 football court cantilever stadium roof design

2. football stadium structure selection and layout

The football stadium architectural design requires as few structural members as possible so as not to affect the visual effect of the interior of the stadium. In order to make the roof structure as light as possible and ensure the overall spatial effect, the cantilever stadium roof design structure selection was combined with the characteristics of the building and comprehensively considered the support provided by the substructure.

The steel structure of the football stadium is composed of two parts: the cantilever stadium roof design and the supporting steel structure of the façade. The steel structure roof is about 226m long from east to west and 241m long from north to south. The roof load-bearing system adopts a space truss structure system composed of radial main trusses and circumferential secondary trusses. The main truss includes 68 plane trusses with different spans, each truss cantilevered radially into the stadium, the maximum cantilever span is 37.3m, and the minimum cantilever span is 12.8m. The main truss adopts a plane truss with variable section and height. The maximum height of the root of the cantilever truss is 4.2m, and the height of the end truss gradually changes to 1.2m. The secondary trusses are arranged in the circumferential direction, including 5 belt-shaped plane connection trusses in the middle and three-dimensional trusses of the inner and outer rings arranged through the length. The circumferential secondary truss not only serves as the secondary load-bearing system of the upper roof but also reduces the lateral calculation length of the main truss. In order to enhance the overall stability of the structure, horizontal supports of the upper and lower chords are arranged between the local main trusses. The radial main truss, the annular truss, and the horizontal support together constitute a stable geometrically invariant system, and the structural composition is shown in Figure 2.

Fig.2 The composition of the main structure of the roof

A support system consisting of vertical support and horizontal support is arranged on the facade of the structure. This system not only serves as the load-bearing frame of the facade aluminum panel curtain wall but also increases the horizontal rigidity of the overall structure. The entire roof steel structure is supported on the outermost ring column of the lower stand. Each main truss and the supporting column have 5 to 6 connection nodes, as shown in the main truss section in Figure 2(d). The supporting column of the steel structure is not only subjected to a large force but also has a complex force state, which has a great impact on the overall safety of the structure. In order to ensure the safety of the structure, the supporting columns of the steel structure are made of steel concrete columns, and the column sections are all 1000×1500, the column steel is H1100 × 600 × 20 × 30 (Q345B). Roof steel structural members transmit the internal force of the upper roof directly to the steel in the column through the connecting nodes. Among them, the top support of the column is made of cast steel + spherical steel support node, and the rest of the nodes are made of pin shaft nodes. The lower part of the concrete stand is divided into 4 sections by setting expansion joints, and the upper steel structure has no joints.

The roof shape of the football stadium is novel and unique. By comprehensively considering the visual effect of the building and the stress requirements of the structure, the structural form adopts a space truss structure system composed of radial main trusses and circumferential secondary trusses and supports.

About Us

About Us 2022-07-25

2022-07-25