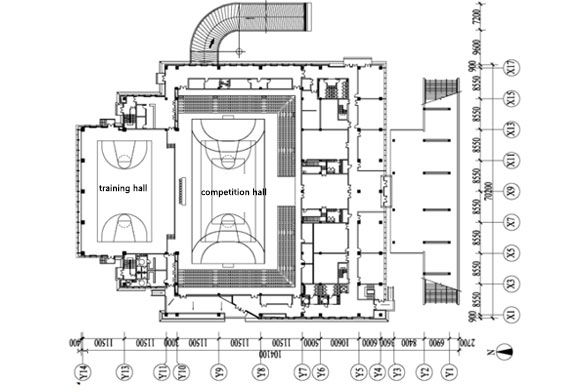

The appearance of the steel stadium as a whole is a giant “battleship”, modeling is novel and unique, The building is high in the south and low in the north and sets matches, training, performance, and other functions. Its north side is the training hall (it can be used as the performance stage as well). The south side is set as the competition hall, with a total construction area of about 14907 ㎡, and its horizontal projection is an irregular rectangle. The main structure of the stadium is a reinforced concrete frame structure, which is set as one underground layer and three above-ground layers. The roof part adopts a steel structure. Its engineering design service life is 50 years, structure safety grade is two, and seismic fortification category is b. In the selection stage of roof steel structure, three structural systems are analyzed and compared: space frame structure, tension beam structure, and space truss structure.

Figure 1 Stadium Building Floor Plan

Table 1 Comparison of advantages and disadvantages of different stadium steel structure design systems

|

structural system |

advantages |

disadvantages |

|

Space frame structure |

Space structure, simple force transmission path; Economically cost-effective; Convenient construction and installation |

There are many rods, and dense rods affect architectural aesthetics. This structure has weak adaptability to the flexible arrangement of hanging load. |

|

Beam String Structure

|

The structure is light and simple, and the force flow transfer is clear. Can span a large space |

Wind load sensitivity, High requirements for indoor net height; The amount of steel used and the comprehensive cost are higher than the conventional space structure system |

|

Space truss structure |

The appearance is simple with smooth lines, it can also create lots of shapes. High stiffness, good geometric characteristics. It is good for rust prevention, maintenance, and cleaning |

Material strength can not give full play to the use of steel is larger than the grid structure; Processing and lofting of intersecting joints are complicated; High requirements for welding quality, welding workload |

The spatial space frame structure has relative advantages in terms of structural integrity and the amount of steel used in the structure. However, considering that the steel roof of the stadium is not equipped with a suspended ceiling, the dense rods of the space frame structure may affect the aesthetics of the building, it is not suitable to use a spatial space frame structure.

Because of its light shape, the tension beam structure is more expressive in architecture. As the tension beam is a wind load-sensitive structure, the lower cable may be compressed and quit under the action of wind suction, which will substantially change the overall stress state of the tension beam structure and affect the safety of the structure. If the dead weight of the beam is increased to balance the wind suction, the structure will be uneconomical. Therefore, the spatial truss structure is selected as one of the basic structural forms of the steel roof of the stadium after considering the aesthetic demand of the building, the mechanical performance of the structure, the overall cost of the structure, and other factors.

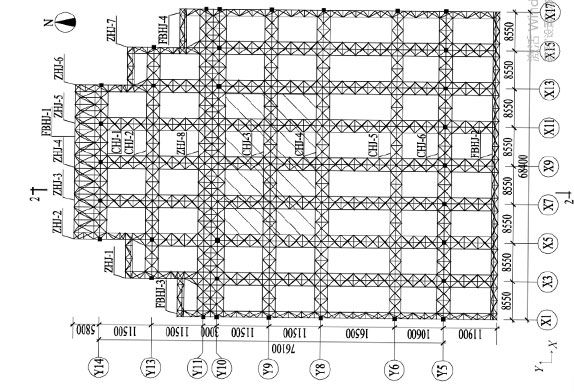

Due to the irregular column network of the substructure, the span of the main truss is different, and its maximum span is 76.1m, which is larger than the short span of the roof of 68.4 m. The force transmission path of the whole structure is changed by using the boundary conditions of the substructure reasonably and setting the rigid transfer truss. With the transfer truss as the boundary, the main trusses are arranged along the short-span direction of the structure on the south and north sides of the roof. The load will be transferred from the main truss to the transfer truss, and then from the transfer truss to the lower concrete structure. The transmission path is clear, and the structure is uniform and reasonable

(1) make full use of the lower column space frame structure, at the boundary between the academy and the competition hall, a main conversion truss composed of two inverted triangular space trusses is arranged in parallel to form a rigid boundary of the whole structure, and it divides the irregular roof area into two, the span of the north convex roof maximum is 23 m, and the span of the south rectangular roof is 50. 1 m. In these two roof areas, the main and secondary truss structures are arranged in the vertical and horizontal orthogonal directions, and the structural design is carried out respectively.

(2) The maximum span of the main truss is greatly reduced. In order to make the roof look lighter, the height of the truss is reduced to 3.2m, and the maximum height-span ratio of the structure is about 1/16. At the same time, the cross sections of the structural rods were optimized, and the truss string cross sections changed from ∅245×16 to ∅121× 6. The belly rod has a minimum ∅76×4 section and a maximum ∅219× 16 section. A total of nine-rod sections are used.

Figure 2 Roof structure of the prefab steel stadium

About Us

About Us 2022-10-19

2022-10-19