1 Power Plant Dry Coal Shed Project Overview

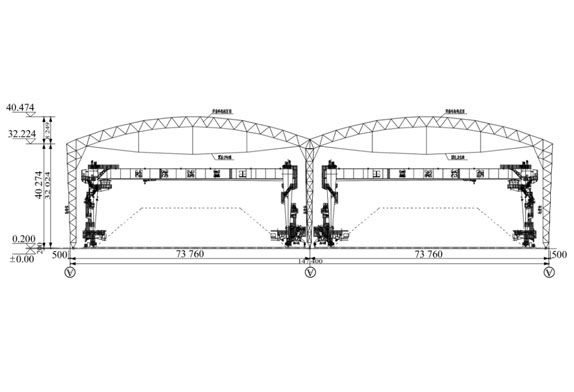

The coal yard of a power plant was originally designed as wind and dust-suppressing wall structure. The surrounding dust-proof wall foundations and bucket turbine foundations have been constructed. After approval, large dry coal shed roof cover steel structure was used (Figure 1-3). The dry coal storage shed is equipped with 2 large bucket turbines with a span of 60 m and a height of 28 m, the length of the coal yard is 301.5 m, with two consecutive spans, and the span of a single span is 73.7 m, and the total span is 147.4 m. The structure above the 0.2 m elevation is an all steel structure, and the foundation uses the original dustproof concrete independent foundation of the wall, that is, no major renovation is required, and the original windproof and dust-suppressing wall foundation is used.

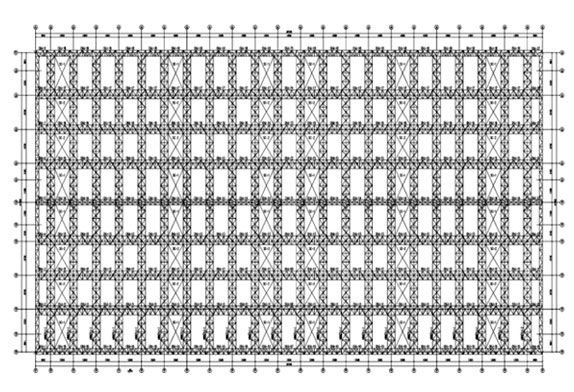

FIG.1 The overall layout of the steel structure

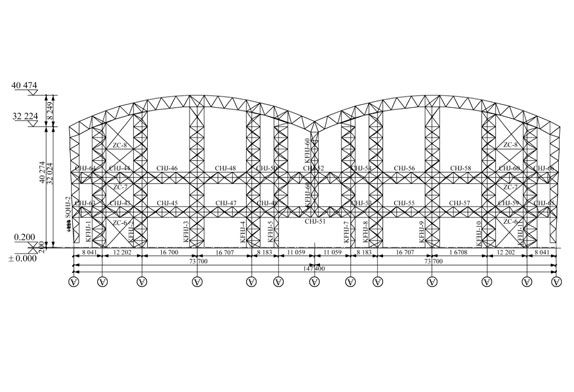

FIG.2 Section drawing(height: m; Length: mm)

FIG.2 Section drawing(height: m; Length: mm)

FIG. 3 Elevation of gable wall (height: m; Length: mm)

2 Steel structure dry coal shed introduction

1) Determine the overall dimensions and structural form of the dry coal shed building: the two bucket turbines have been in operation, and there are two-column foundations of the original wind and dust-suppression walls at the positions of the columns on both sides. It is located in the middle of the track foundation of the two bucket turbines. After comparing and analyzing various schemes, the tension string truss scheme is finally determined. The roof member adopts the tension string truss, and the lattice column adopts the variable section form, which is narrow at the bottom and wide at the top, and the roof member and the lattice column are rigid. Connection, lattice column foot adopts the form of connection, this scheme has the following advantages:

2) The roof member adopts a string truss structure with a span of 74.7m. The string structure is light in weight and has a good bearing capacity, which can better solve the problems of bearing and vertical stiffness.

3) Roof members and lattice columns are rigidly connected, and the haunches are added to form a portal-like rigid frame structure, which can effectively control the lateral displacement of wind loads and earthquakes.

4) The column foot is connected by a joint. When the wind load and earthquake activity, the upper structure only transmits the shear force to the foundation and does not directly generate the bending moment, so that the original foundation can be used. The roof string truss is an inverted triangular three-tube lattice Truss, the chord section is 219 mm X 10 mm, the material is Q235B, the truss chord and the web are connected by intersecting welding, the tension truss cable adopts 6 bundles of 1×7 diameter 15.2 steel strands, and the cross-sectional area is 824 mm2. The tensile strength of the steel strand is 1860 MPa, the anchoring device adopts a 6-hole clip-type anchoring device, and 3 vertical rods are set between the tension string truss and the stay cable. The vertical rod section is a 180 mmX8 mm steel pipe. A 351 mmX40 mm anchor cup is set, and the lower chord and web member of the tension truss are welded to the anchor cup. For tensioning and adjustment, a tensioning reaction frame, anchoring nut, adjusting screw, and other devices are set up, and the cable nodes are anchored.

The steel structure of the power plant dry coal shed adopts the construction method of assembling at the ends and pulling the skeleton to the other side. During the sliding, the two trusses slide together, and the secondary truss and cross bracing between the two trusses have been installed, and the sliding The moving element is a stable space force system. The large-span design is controlled by the structural stiffness. The project also needs to consider the overall lateral stiffness requirements of the structure, and at the same time consider the utilization of the original foundation. This is the difference between this project and other large-span structures. point.

About Us

About Us 2022-08-31

2022-08-31