1. Project Overview

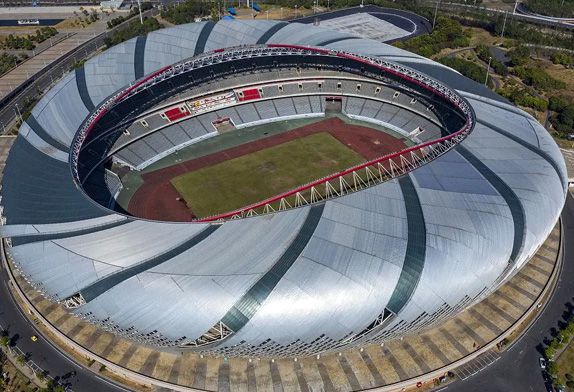

The roof of the comprehensive gymnasium of Nanchang International Sports Center adopts an orthogonal inclined space frame structure, which is at an Angle of 45° with the rectangular edge. The maximum inclined span of the middle truss is 117m and the truss height is 6m. The east and west side of the VIP hall and the audience hall span is small, truss height 2.5m. The steel roof is supported on top of reinforced concrete columns around the stadium stands and around the building’s periphery. Cantilever 6m truss along the outer ring of the roof, the roof main truss intersection point using welding ball node, the external cantilever truss and arch truss intersection node using intersecting welding node.

The roof of the gymnasium was placed in the south high and north low tilt, the highest elevation of the south side of the structure is 32.95m, the north elevation is 25.9m, the east and west elevation are 19.4m, the highest elevation of the arch truss is 56.37m, the projected area of the whole roof steel structure is about 17,000 square meters.

2.Key points and difficulties of the project

1) Measurement control

The roof of this project is an orthogonal diagonal space frame spatial structure, with inconsistent elevation and irregular shape. The key and difficult points of measurement are the installation and positioning of the support frame and welding ball, and the high-altitude bulk is a dynamic process, so the measurement control network needs to be reviewed regularly.

2) The erection of the support frame

The function of the support frame is to provide temporary working platform for the segmental lifting of the truss. In order to ensure the safety of hoisting, the foundation of the support frame, its overall stability and the reinforcement of the support stand are particularly important.

3) Truss hoisting

The technical parameters of truss hoisting are quite large, among which the roof truss is 26.02t, the longest is 43.4m, and the highest is 41m. The arch trusses are 56m high. The hoisting machinery selected for this purpose are 200T truck crane and 15m crawler crane. Table 1 Comparison of space frame construction methods

|

Construction method |

Full of scaffolding high in bulk |

Installation of hoisting and full – floor scaffolding |

Slip to install |

Segmental hoisting

|

|

Construction analysis |

The most common method of space frame engineering installation is less affected by site conditions; In view of the large space volume of the project, the amount of scaffolding is large, the height of the scaffolding. High, complex floor reinforcement, not easy to ensure the construction period, and cumbersome structural calculation |

According to the structural characteristics of the project, the middle area can be selected as a whole to lift, the four corners of the installation method of full scaffolding; The deficiency is that the promotion can not be in place at a time, and there are gaps in the area. Construction safety and installation accuracy are difficult to control |

According to the structural characteristics of the project, the middle area can be selected as a whole to lift, the four corners of the installation method of full scaffolding; The deficiency is that the promotion can not be in place at a time, and there are gaps in the area. Construction safety and installation accuracy are difficult to control |

The plane trusses of the space frame structure of the roof in this project are regular, with a spacing of 9m. The inner and outer rings can be hoisted synchronously, which is very beneficial to ensure the construction period. But the safety of personnel ascending and working at height is the key and difficult point of this installation scheme |

|

Evaluate |

Feasible and difficult |

Feasible and difficult |

Infeasible |

Feasible |

In general, the main structure of gymnasium project adopts the construction technology of segmental hoisting, which is divided into inner ring and outer ring for hoisting. The overall installation sequence is: the outer ring is hoisted first, and the inner ring is subsequently repaired and installed. Therefore, it is considered that 2 150T crawler cranes should be installed off-site and installed along the direction of the main truss from both sides. The site is mainly set up with a 200T truck crane, the construction direction and the outside structure to keep synchronized.

About Us

About Us 2022-05-13

2022-05-13