Space frame construction method

The installation method of the space frame structure should be comprehensively determined according to the type, force, and structural characteristics of the structure, under the premise of ensuring quality and safety, in combination with the schedule, economy, and technical conditions of the construction site.

1. scaffold method(High altitude bulk method)

Individual elements are assembled in place at actual elevations; members and joints or prefabricated sub-assembly elements are assembled directly in their final position. Full scaffoldings are usually required for this type of erection. Sometimes, only partial scaffoldings are used if a cantilever erection of the space frame can be executed. The elements are fabricated at the shop and transported to the construction site, and no heavy lifting equipment is required. The full-scale scaffolding method requires that full-scale scaffolding be erected under the construction area to form construction operations. The platform is used for construction workers to work on the platform. The advantage of this method is that the construction is simple, and the scaffolding is removed after the high-altitude splicing and forming. In addition, a large number of construction workers are completed at high altitudes, resulting in low work efficiency and increased safety risks.

The high-altitude bulk method is to directly assemble rods and nodes (or small block units) into a whole at the structural location. It is suitable for screw-connected space frames, does not require a lot of lifting equipment, does not require high construction sites, but has many high-altitude operations, and the rods are partially deformed by force. This construction method is widely used and can solve the assembly of most geometric forms of space frame structures. However, due to the large local deflection and deformation of the space frame and the easy occurrence of instability during the high-altitude bulk method installation, in most cases, large-scale temporary support measures must be taken, which leads to this problem. This method is generally only suitable for the assembly of small-volume space frame structures.

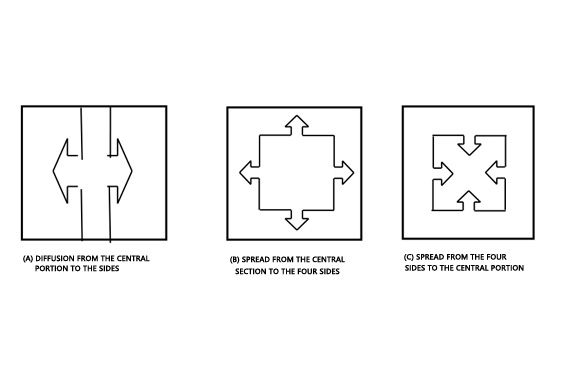

Diagram of the total sequence of the space frame structure

In the construction process of the high-altitude bulk method, the requirement of aerial positioning of rod joints is relatively high, and a reasonable construction sequence should be adopted according to the space frame structure form and boundary conditions. The form of support can be divided into fragment sliding support method, local point support cantilever method, and full red support method. The piece-slip support method is to set a pulley with the track at the bottom of the support frame, and the lower support moves as the assembly position moves. This method is suitable for the space frame structure with a regular shape and a large aspect ratio. The sliding support can not only control the deformation of the space frame but also reduce the pressure of the surrounding trestle. The local point support cantilever method is to extend from the edge of the structure to its interior, according to the position of the support calculated in advance to set the support; Full support method refers to the lower part of the whole space frame set up full of scaffolding to support the space frame structure, it has the characteristics of convenient construction, scaffolding workload, high accuracy of installation.

The space frame is divided on its plan into individual strips or blocks. These units are fabricated on the ground level, then hoisted up into their final position, and assembled on the temporary supports. With more work being done on the ground, the amount of assembling work at high elevations is reduced. This method is suitable for those double-layer space frames where the stiffness and load resisting behavior will not change considerably after dividing into strips or blocks, such as two-way orthogonal latticed space frames, orthogonal square pyramid space frames, and those with openings. The size of each unit will depend on the hoisting capacity available.

This space frame construction method can reduce the workload of aerial installation and help to ensure the accuracy of construction and installation.Shortening the installation period can reduce a large number of temporary supports compared with high-altitude splicing, which can greatly reduce construction costs; however, in the application process of this construction method, attention should be paid to the quality of the divided unit blocks or unit strips. The performance of the car hoist is consistent, and attention should be paid to the control of the installation quality of the unit block or unit strip and the ability to resist deformation to meet the requirements of high-altitude hoisting.

The block assembly method is to splice the space frame on the ground into blocks after comprehensively considering the working conditions of the space frame and the actual conditions of the construction site, then hoisting the spliced space frame-blocks in the air, then installing them, and then connect them. This can reduce the amount of high-altitude construction work, and shorten the construction period.

In summary, this space frame construction method is mostly used in the construction of space frame structures where the division of unit blocks or unit strips has little effect on the bearing capacity and resistance to deformation of the entire space frame structure.

The whole space frame is assembled at ground level so that most of the work can be done before hoisting. This will result in increased efficiency and better quality. For short and medium spans, the space frame structure can be hoisted up by several cranes. For long-span space frames, temporary posts are used as the support and electric winches as the lifting power. The whole space frame can be translated or rotated in the air and then seated in its final position. This method can be employed in all types of double-layer space frames.

The lift-up method is divided into the high-altitude sliding method, the overall jacking method of ground assembly, and the overall lifting method of ground assembly.

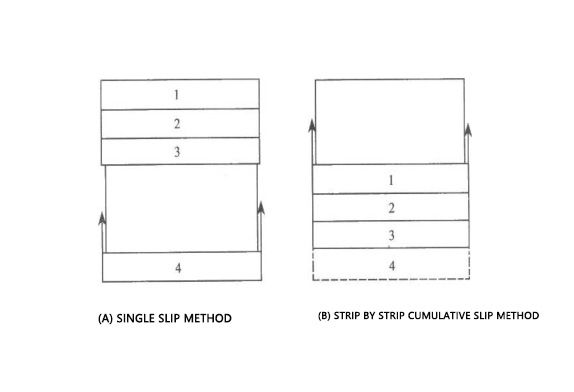

High-altitude sliding method: This method is splicing rods on the ground to form a sliding unit, and then hoisting the sliding unit to the set sliding track for assembly; The high-altitude sliding construction method can be divided into single slip method and strip by strip accumulation slip method, and its applicability is prominent. This method can be used in parallel with other civil engineering and shorten the total construction period. Especially in the site is narrow or across other structures, equipment and cranes can not enter the more suitable. The stadium roof or theater and other large-span projects such as civil construction, decoration, and equipment installation can play an economic effect. Single slip method: slip strip units one by one from one end to the other end in place and install, and then connect them in the air, that is, slip strip by strip and connect the whole strip by strip. Detailed accumulation sliding method: first to strip one end unit sliding distance (can be connected to the second unit width), after fitting of the second unit, the two together to slip a distance (width ditto), and connect the third article, three sliding distance together again, so until to the last one unit operation.

high-altitude slip method

The overall jacking method of ground assembly: after the space frame is assembled on the ground, the space frame is lifted to the predetermined installation position by lifting equipment, and then adjusted and fixed. The advantage of this method is that the use of ground assembly can effectively shorten the construction period, improve the construction efficiency of operators, and ensure the safety of construction operations.

The overall hoisting method of ground assembly: the space frame is assembled on the ground, and the space frame is lifted to the installation position by crane equipment, and finally adjusted and fixed. The advantage of this method is that the ground assembly shortens the construction period, improves the construction efficiency, and the workers are Safe and easy to guarantee.

Therefore, the specific situation of the project should be considered when planning the installation and construction method of the space frame project, such as space frame size, space frame cost, the type of the space frame, and so on.

If you have a space frame project that we can help you analyze, design, and install, please contact us: Marketing01@cnxzlf.com, Looking forward to your sharing.

About Us

About Us 2021-08-17

2021-08-17