1 Project Overview

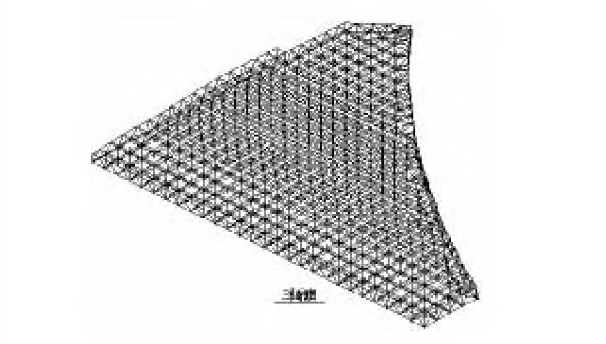

The space frame structure of the emergency dry coal shed in the coal pile area of the power plant is irregular pentagon in plane shape, with a length of 121.958m and a maximum span of 99.949m. The roof of the coal pile area is a double-layer flat space frame, which is supported by reinforced concrete columns around the perimeter. The space frame structure is in the form of quadrilateral cone cylindrical space frame shell structure, and the joints are connected by bolt balls (as shown in Figure 1).

Figure 1. 3D perspective view of flat space frame structure

2 Engineering characteristics and on -site installation methods process

Under normal circumstances, in order to cover the large span, ensure the stiffness and strength of the structure, save the amount of steel space frame, the structure of the large span space frame is basically designed as a three -layer space frame or a three -layer space frame and a two -layer space frame combination. The height (thickness) of the flat space frame increases with the increase of span L. Generally, the thickness of the flat space frame is taken (1/14-1/16) L. For example, L = 100M, its height H = 100/15 = 6.7m, after the height increases, the grid will increase, otherwise the angle between the abdominal rods is small and the interchange is difficult, so the upper and lower space frame will be 6 ~ 7m in 6 ~ 7m, at this time, its pole is 7 ~ 8m long. In the axial force rod of the space frame, the length and slenderness ratio of the pressure rod takes the control effect, so the section of the rod is naturally large, and the specification of the bolt ball becomes larger, and the natural steel amount increases sharply.

This project is a double-layer large-span unequal height flat space frame, the maximum span of nearly 100m, belongs to the extra-large span building, and its shape is irregular, the unit with a large amount of steel, the installation personnel requirements are high, to increase the deflection control of the space frame is very difficult, due to the narrow site, and synchronous operation with civil construction, so it is not suitable for the flat space frame conventional overall jacking installation method. According to the characteristics of the project and the actual situation, the space frame is assembled on the ground, and the overall lifting is carried out with the car crane. After the installation of the initial space frame is completed, the remaining space frame is installed in high altitude bulk . At the same time, with the increase of the span of the space frame, the temporary support of steel pipe column should be added synchronously until the installation of the space frame is completed. This method has the advantages of fast construction speed, small occupation of the site, and can better confirm the construction quality and safety of the project, which is the most suitable construction method for the project. Firstly, three QY50K cranes are used to lift the grid frame in construction area 1 (10-11 axis, L-11-L-12 A-E axis area) as A whole. After the installation and positioning check is correct and temporary fixed, one 25t car crane is used to carry out the high-altitude bulk construction of the remaining uninstalled space frame, and the installation sequence is from construction zone 1 to the side wall of construction zone 3 and Zone 2. Finally, the side wall of the construction area 3 and 2 is installed and closed to the middle.

3 The installation method of the space frame

3.1 Construction process process

Construction preparation T foundation retest – ground pre-assembly of starting grid unit T starting grid installation – high altitude bulk of remaining grid – setting temporary support of steel pipe column – size check T removing temporary support of steel pipe column.

3.2 Construction preparation and foundation re -test

After entering the field, the number of components should be counted, check whether the appearance quality and specifications are consistent with the quality certification file and design file, strictly control the quality, and the installation process shall not enter the installation process for materials and structures with defects such as quality. Reserve the pre -assembled venue of the small patchning unit and the starting space frame ground, and clean up. Before the construction, the supervision and civil building of the rack support basics were reviewed to ensure the quality, elevation, central axis, geometric size, parallel degree, positioning benchmark point point, etc. of the embedded parts. The axis is marked and protected.

3.3 Ground pee-assembly of starting space frame unit

The space frame unit is assembled from the pole, bolt ball and accessories. Installation of the top and bottom chord at the same time, tracking and detecting the installation size. Construction order: bottom chord joint – bottom chord rod – the web chord and top chord joint – top chord – correction – tightening bolts.

Assembling of the bottom string rod and ball: connect the high -strength bolt threads that connect the string ball and the pole, tighten in place at a time

3.4 Space frame high -altitude bulk installation process method

Construction process: component sorting -ground assembly small cone -hanging small cone -installation of high altitude.

Component sorting: The components and balls that will be transported to the scene are stacked according to the specifications and models, and are marked for easy use.

Ground assembly cone: the construction personnel can be divided into two parts when high altitude bulk loading, one part is the ground unit assembly personnel, and the other part is the high altitude installation personnel in place.

Installation procedure: First, the ground assembly personnel will assemble the grid to be installed into a continuous unit grid on the ground according to the requirements of the drawings, and then the continuous unit grid will be lifted to the corresponding position of the installed space frame in the air by the crane, and then the continuous unit grid and the installed space frame will be connected into one by the high altitude bulk personnel, and then continue the installation of the next unit.

Lifting small cone: tie two tether (brown rope) to the upper (lower) chord rod, the length of the two tether should be well controlled, the lifting of the triangular cone to the actual installation position in the air, the deflection Angle should not be too large, so as to facilitate the installation of high altitude personnel.

High altitude bulk: in bulk construction operation, the crane will be assembled on the ground good small unit triplex directly transported to the installation site, at each connection point by an installer in the high altitude. The installer connects the high-strength stud with the stud ball hole after receiving the corresponding mounting rod. The initial connection should be screwed into 3~5 buckle, echoing the installation of other installation team members, until all the installation bolts are screwed into the corresponding thread hole of the stud ball, and then tighten the high-strength bolts in place together, to avoid a high-strength bolt first tight dead, which will cause other high-strength stubs to be difficult to install. After all the rods are fastened, the tether can be removed, the hook can be loosened, and the next unit can be installed. Repeat until the installation is complete.

At present, with the continuous improvement of the design technology level, the production scale is expanding, the span is increasing, and the construction and installation methods are also changing with the development of technology and the accumulation of experience, and constantly innovating.

At present, the structure of the Chinese flat bolt ball space frame has continued to expand with the level of design technology, the scale of production has continued to expand, and the span has continued to increase. The construction and installation methods are also changing with the accumulation of technological development and experience.

About Us

About Us 2024-06-28

2024-06-28