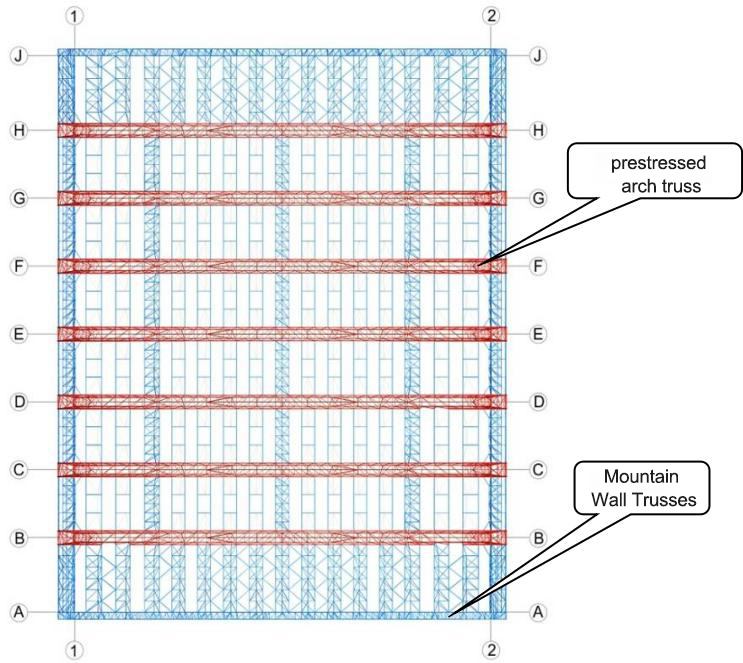

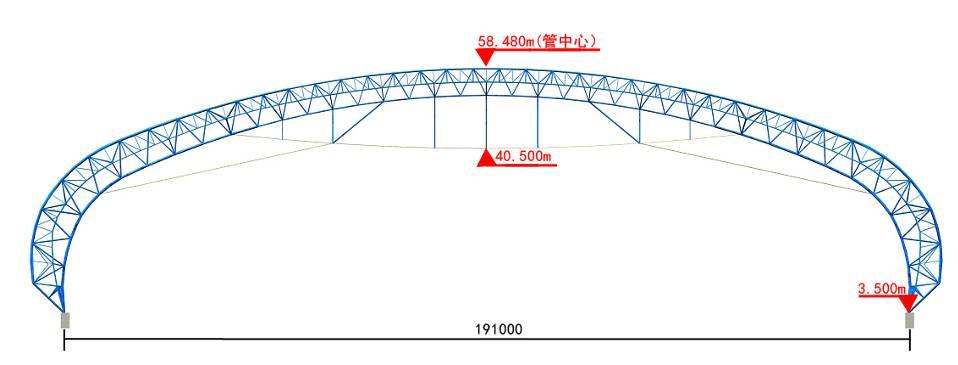

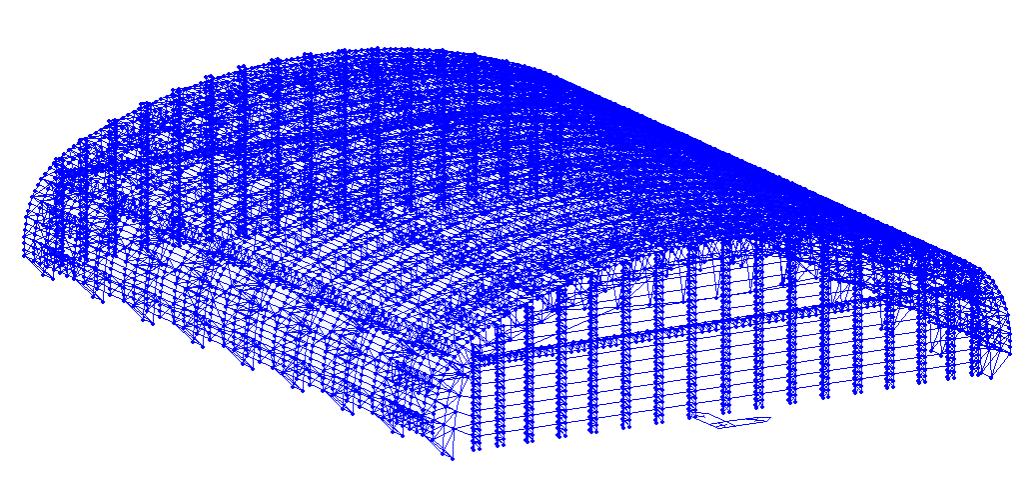

The steel structure project of the closed coal yard of the power plant adopts the technologically advanced prestressed arch truss structural scheme, the structural span reaches 199m (net span between supports 191m), the truss spacing is 30m, and the weight of the single-bay prestressed arch truss reaches 450 tons. The longitudinal length of the closed coal yard is 252m, the building area is about 48,000 square meters, and the total height of the building is about 58m. 9 bays of quadrilateral arch trusses are used for the main structure, the width of the trusses’ upper chord is 6m, the width of the trusses’ lower chord is 4m, and the lower part of the trusses are equipped with pre-stressed tension cables and diagonal cables, which are connected through the V-type gussets, and the maximum vertical height of the tension cables is 12m, and the tension cables, the diagonal cables and arch trusses are working together, which forms a multi-order prestressed structural system. The tension cables, diagonal cables, and arch truss work together to form a multi-step prestressed structure system.

The structural plan, section, and 3D axonometric drawings of the project are shown in Figures 1 to 3.

(1) The tension cables of the project are arranged along the lower chord of the main truss, which mainly serves to balance the thrust of the tension truss on the columns on both sides. Since the supports on both sides of the tension truss are fixed-hinge supports, the designers have put forward clear requirements on the shear, tension, and compression resistance of the supports, so the prestressing force needs to be applied in a way to satisfy the design intention, i.e., reducing the thrust of the tension truss on the supports to improve the structural stressing performance.

(2) The steel structure of this project adopts the construction scheme of “segmental lifting + zonal lifting”, and the construction process is divided into several states, such as truss assembly, synchronous lifting, tensioning of tension cables, roof construction, etc. The tension cable force in each state is different from that of the other. The cable tensioning force is different in each state, to achieve the design requirements of the structural shape, structural internal force, bearing position, and force, the application of prestressing is a key process, so it is necessary to carry out construction simulation calculations for the whole process of construction and monitor the whole process of construction to ensure the safety and quality of the construction process.

(3) The maximum span of the project structure is 191m, and it is necessary to ensure that the structure is a stable stress unit during the tensioning construction to prevent the structure from destabilizing during the tensioning.

(4) When the trusses in the lifting area are lifted, the tensioning cables should be pre-tensioned to ensure that the trusses can be accurately positioned.

coal shed 1

coal shed 2

coal shed 3

About Us

About Us 2024-05-29

2024-05-29