1. Overview of limestone pile shed project

The 4000t/d clinker cement production line of a cement factory in Oman is flat and about 160 m above sea level. It has a subtropical climate and is warm all year round. From November to the next May for winter, the average temperature is 18 ℃ to 25 ℃, occasional rain, the hottest for July to August, the average temperature is 35~45℃, up to 55 ℃, humidity 99%, the average rainfall of 40 mm, wind 140 km/h, wind direction is mainly northeast, 7~9 sandstorms every year.

The limestone pile shed is a limestone space frame pile shed as the foundation roof structure, span diameter of 98 m, the arch of the space frame 26.2m, the roof adopts a single layer of color steel plate, the optimal design of the space frame, the steel quantity is only 24 kg/m. The local area is a high temperature and humidity area, and the concentration of corrosive medium in the atmosphere is high, therefore, the anti-corrosion treatment requirements on the surface of the space frame are very strict, we use the surface spray treatment.

2. Dome Steel Structural design

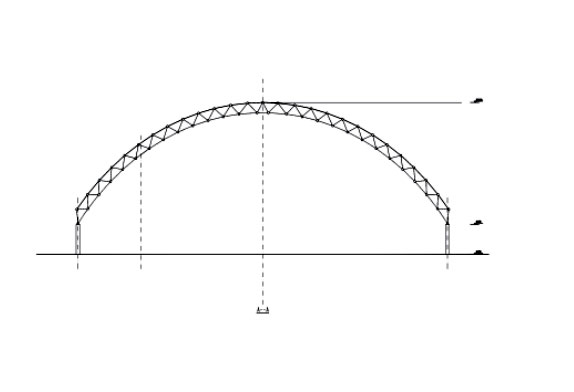

The Oman a cement plant space frames span reticulated shell is larger, in order to satisfy the requirement of the whole structural stiffness, net shell rack generally in the form of four pyramid space truss, and four cone shell space frame layout has three forms, namely inclined put four prism net shell, orthogonal diagonal four cone reticulated shell and orthogonal square pyramid four net shells, the three forms are used in the construction of large span reticulated shell rack, Through comparison of the three forms, optimization of the structure and comprehensive comparison of design experience, this project adopts orthogonal square pyramid net shell and net frame, so that the force transmission of the structure is more uniform and clear (FIG. 1).FIG. 1 Orthogonal square space frame shell space frame frame

3 Installation

Due to the special situation of the site, the scaffolding can not be set up. Therefore, it is proposed to adopt the method of setting up local scaffolding and aerial lifting for space frame installation.

3.1 Erection of scaffolding

(1) Scaffolding shall be set up in the starting area of the installation of the space frame, that is, at least 5m wide ring scaffolding shall be set up along the inner side of the space frame base according to the height of the foundation.

(2) according to the requirements of scaffolding erection.

3.2 Installation of space frame The space frame project is equipped with partial scaffolding, and the large tonnage crane is mainly used to lift the parts to high altitudes for bulk installation of the network frame. Before installation, the network frame parts to be installed are transported to the scaffold platform and placed evenly. After the installation of the support, at least two space frames are installed along the circumference as the starting area of the network frame installation. After the starting area is installed, the rest parts shall be installed in strips and blocks. Large tonnage cranes shall be used to lift parts of the network frames installed in fragments on the ground to the specified positions, and gradually install them upward along a circle.

(1) Before installation, the position and size of embedded parts provided by civil construction should be rechecked, and the installation can be performed only after meeting the requirements.

(2) Before installation, the space frame parts to be installed are transported to the working platform and placed evenly. After the installation of the support, the installation is carried out in accordance with the square quadonal network frame installation method. The connection between the lower string and the ball: according to the drawing number, connect the lower string and the lower ball and tighten it in place. The connection of the belly rod and the bolt ball: the belly rod and the upper string ball and the lower string ball are connected to form a four Angle cone, the belly rod and the upper string ball connection must be in place in turn, and the lower string ball connection can not be tightly in place, mainly to adjust the upper string leaves room. The connection of the upper string: the connection of the upper string, from inside to outside, the upper string and the upper ball should be tight with the belly rod and the lower string ball. ④ According to the above method, in accordance with the order, one by one space frame installation until the end of all. In the installation process of the project, attention should be paid to the axis size, high-strength bolts must be tightly secured, the overall size control and deflection control, to ensure the overall quality of the space frame. The installation of the space frame must be carried out in strict accordance with the design installation drawing. When installing, the support must fall on the embedded steel plate to ensure that the upper and lower chord axes are located in the same horizontal plane, and ensure that the coaxiality meets the standard or design requirements.

The project with advanced design and high-quality high-speed production and installation of the owner’s praise, successfully passed the acceptance of the local authorities. During the installation period and after the completion of the project, foreign customers have taken the initiative to request our company to participate in the bidding of the related space frame engineering, which shows that the project design and construction has won international honor for us and won a place for us in the foreign space frame market. The engineering practice shows that the bolt-ball node network frame has its obvious advantages in the use of large-span structure, most of its production work is processed in domestic factories, the production quality is easy to ensure, can be packed and transported, installation using high-altitude bulk, convenient and fast, do not need large equipment, and the installation work can be carried out across. In a word, bolt-ball joint network frame can obtain obvious technical and economic benefits as a supporting sub-project in cement production line abroad.

About Us

About Us 2022-09-23

2022-09-23