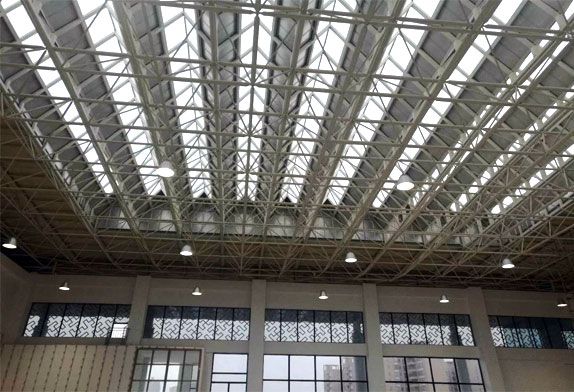

1. Tennis Court Project Overview

The tennis complex roof adopts a steel structure, the tennis complex covers a building area of 15900m², with a total of 5 floors, one underground floor, four floors above ground, and 3 floors attached to the roof part. The building height is 16m and the total height is 28m. The foundation adopts pile foundation and independent foundation, and the main structure adopts the composite structure type of reinforced concrete frame structure + steel structure + space frame structure. Engineering steel structural members mainly include three types: rigid steel column, fasting truss beam, and tube truss. The parameter information of these three types of members is shown in Table 1.

2. Technical requirements of engineering construction

(1) All steel structures transported to the construction site should have qualification certificates. Construction personnel should check the quality and appearance of components. Once problems are found, they should immediately correct the problems encountered, so as to improve the quality of the structure and make it meet the actual construction needs of the project.

(2) For the installation of steel structure draw a set of the flow chart in line with the specific situation, in strict accordance with the flow chart installation, to check the situation of the anchor bolt before installation, if there is a difference between the specific space position and the design, to correct in time.

(3) Design a reasonable installation sequence of components to form a stiffness that can meet the requirements, ensure the stability of the structure, and eliminate various errors in the installation of steel structures.

(4) When installing a steel structure or column, it is necessary to complete the installation of beam and support in the structure in time. If necessary, wind rope should be added, and the steel structure can be fixed through its application.

(5) When installing a steel structure, temperature changes should be controlled to avoid adverse effects on the perpendicularity of components due to temperature changes.

(6) The installation of steel structure is complex work, the development of installation will be affected by the welding environment, temperature, humidity, and other factors, so it is easy to appear various defects such as welds during the welding, welding should consider the influence of various factors, for unqualified welds should be reworked in time.

Table 1 Three types of component parameter information

|

Component type |

Distribution area |

Quantity (pieces) |

Weight of the heaviest member (ton) |

Use lifting equipment |

|

Stiff steel column |

Axis 6~16 |

72 |

2.7 |

lorry-mounted crane 25t, 100t |

|

7.1m Elevated fasting truss |

Axis 6~16 |

403 |

8.1 |

lorry-mounted crane 120t |

|

14.9m Elevated fasting truss |

Axis 6~37 |

2690 |

16 |

crawler crane 260t |

|

Truss |

Axis 2~6 |

1800 |

3 |

50t car |

3. Technical guarantee conditions for steel structure construction

(1) Arrange the construction sequence strictly according to the specific requirements of the project construction. For the key projects in the project construction, increase the investment in construction, technology, mechanical equipment, etc., to ensure that the construction can be carried out in accordance with the specified sequence, and on the basis of ensuring the quality of the project, the project can be completed on schedule.

(2) Plan the transportation route of construction materials. If necessary, no-load transportation shall be adopted. During transportation, it is necessary to make clear whether there are obstacles on the transportation path.

(3) Before the construction of all the machinery and tools, the mechanical equipment should be maintained, its performance should be checked, the mechanical equipment should be prepared for operation, the construction site investigation should be done well, the construction should be organized scientifically, and the construction should be carried out smoothly.

(4) To do a good job in the disclosure of construction technology, the staff in each construction position should be positioned for regular training, clear post responsibilities.

(5) Before the hoisting operation officially begins, the surveyor should check the plane position and elevation of the support in the construction of the project. At the same time, the strength of the concrete should reach 75% of the design strength, so as to avoid the failure of the project due to the insufficient strength of the concrete, resulting in casualties and other accidents.

(6) In the process of steel structure design engineering construction, a large number of steel wire, clasp, steel wire rope, etc., for each content must do a good job of the corresponding calculation, each content to meet the requirements of the specification after calculation, otherwise it is not allowed to carry out lifting operations.

(7)All kinds of lifting equipment used in the engineering construction site must have a qualified annual inspection certificate, and all welders, electricians, and other construction personnel must hold the certificate on duty, without the corresponding certificate personnel shall not carry out the corresponding operation, so as to avoid the problem of project quality because of the professional ability of personnel.

(8) Before the lifting operation is carried out, it is necessary to carry out a comprehensive inspection of the bearing capacity in use. Before the crane is set down, the supporting footplate of the crane should be used to complete the corresponding laying operation. Through this treatment method, the contact force area can be properly expanded, so as to avoid the damage caused by the large pressure of the temporary road and the hoisting danger. Before the formal lifting operation is carried out, the lifting should be tested in advance, and the height of the lifting should reach 0.2m.

(9) After the completion of the steel beam assembly, the weld and appearance of the steel beam should be inspected on the construction site, and the lifting operation can only be carried out after meeting the requirements.

4. Welding process

During the steel structure welding construction process, the steel columns installed in sections will form many small frame structures during the installation process. In order to reduce the damage to the structure caused by weld shrinkage, the welding sequence from the inside to the outside is adopted to ensure that there is always free weld shrinkage deformation. On-site welding is carried out after the steel columns and frame beams of the running water section are installed, corrected, and fixed. Taking the bolted butt joint of H-beam and H-beam as an example, electrode arc welding and gas-shielded welding are used. Welding needs to tighten the torque of the high-strength web bolts first, then weld the flange, and finally tighten the high-strength web bolts on the basis of cooling the flange weld. Welding flange: The same joint is welded by a welder to weld the lower flange and the upper flange sequentially. If two welders are responsible for welding the same joint, they should be welded symmetrically, and multi-layer multi-pass welding should be used. The welding methods used for box-shaped rectangular column butt joints include flux-cored arc welding, electrode arc welding, and gas-shielded welding. The welding process shall be carried out symmetrically as a whole, and each welded joint shall be welded symmetrically by two welders at the same time. The web butt welds are welded first, and then the flange butt welds are fillet welded. It must be ensured that welded joints are staggered. Multi-layer multi-pass welding should also be used. The welds between every two layers should be staggered by 30-50mm. Each layer welded by two welders shall be staggered. In order to ensure the welding quality of the steel structure, the welding is protected in rainy and windy days to avoid problems such as a sudden drop in welding temperature and damp welding materials. For example, gas cylinders, welding wires, welding machines, etc. are placed in special work sheds. In order to ensure the smooth progress of high-altitude welding, if it is not convenient to set up a windproof shed, a small baffle made of profiled steel plate should be used to close the welding joint. In addition, a lot of effort has been invested in weld repair, such as removing defects such as air holes, slag inclusions, and weld spatulas through electric shovel chiseling, drilling and grinding wheels, repairing undercuts, arc crater dissatisfaction, local defects and insufficient dimensions through welding, And supplemented by targeted welding inspection. Finally, the welding quality of the steel structure was guaranteed, and the follow-up construction was smoothly advanced.

4.1 Continuously improve the comprehensive quality of welding technical staff

With the rapid development of welding technology, various types of welding technology and construction raw materials are constantly emerging. If welding technicians want to ensure the construction quality of building steel structure projects, they need to continuously strengthen their overall quality and continuously improve their technical capabilities. In the steel structure link, welding technology is a highly professional technology. The construction steel structure welding technicians need to undergo strict and professional training and assessment before taking up the job. Only those who pass the assessment can obtain the corresponding qualification certificate. Work with a certificate for actual operation. With the rapid development of the economy of the times, in the process of carrying out the construction of steel structures in construction projects, if you want to break through various types of welding technical difficulties, relevant technical personnel need to keep pace with the times, follow the trend of the times, constantly improve their technical capabilities, and constantly improve themselves The overall literacy of the students, and constantly improve their knowledge reserves in practical work. Secondly, the relevant departments of construction enterprises need to increase the training of welding technicians’ professional ethics and train a group of high-quality, high-professional, and high-tech technical teams, so as to promote the healthy and sound development of construction projects.

4.2 Control welding joint structure

When designing welded joints of steel structures, deformation problems should be avoided, and the number and size of welds should be strictly controlled. During the welding process of steel structure, problems such as a large number of welds and large size are prone to occur, resulting in frequent welding deformation. Therefore, the staff should strictly control the size and number of welds, and choose the appropriate size and shape of the weld groove as much as possible to ensure the bearing capacity of the steel structure and reduce the cross-sectional area. At the same time, when the steel structure is welded, the position of the welding node should be determined on the symmetrical section of the object as much as possible to ensure that the welding point of the neutral axis is as close as possible to the neutral axis and avoid approaching the high-stress area. In addition, the joint form should be reasonably selected to avoid deformation problems caused by stress concentration and high-temperature concentration, and nodes should not be set at multi-directional intersections.

4.3 Control of welding construction conditions

A large number of investigations and practices have shown that there are many factors that affect the welding construction process of steel structures, and the external factors mainly include wind force and the external environment. Therefore, in order to effectively complete the steel structure welding operation, it is necessary to continuously optimize the construction conditions and reduce the impact of environmental factors. First, control the temperature of the welding environment. During the welding process, if the ambient temperature is too low, the temperature value should be adjusted reasonably on the basis of the normal welding temperature to make it consistent with the operating parameters of the equipment, and the equipment used should be preheated to ensure the operating status of the equipment for the next step. One welding construction. And determine the welding method and welding position, select the appropriate welding material, and carry out the steel structure welding construction when the welding operation requirements are met. Second, control the air humidity and try to keep the regional humidity within 90 degrees. If the hair layer of the equipment to be welded is relatively wet, preparations for dehumidification and heat removal should be done in advance to ensure that the surface of the welded component is dry, so as not to affect the welding effect. When dealing with heat and humidity problems, it is necessary to combine the construction situation to clarify the specific characteristics and properties of the steel structure and welded components on the construction site, and then do optimal control; the third is to reasonably control the wind conditions at the construction site. The main control principle is to ensure the stability of the wind speed and welding conditions under the original wind conditions.

4.4 Key points of welding deformation control

The welding quality of steel structure engineering should focus on controlling welding deformation. The welding process that can reduce the deformation and shrinkage of components should be adopted, and the welding sequence should be strictly controlled. When cross joints, T-joints, and butt joints are used, components that are easy to flip or placed in good condition can be welded symmetrically on both sides. For members with symmetrical cross-sections, welding can be carried out around the neutral axis of the member. If there are member nodes that are symmetrical to the connecting rod, then symmetrical welds can be made around the axis of symmetry of the node axis. For asymmetric double-sided groove welds, welding construction should be carried out in strict accordance with a certain order. If the plate is thick, several times of symmetrical welding should be carried out in sequence. For longer steel structure welds, welding methods such as multi-person symmetrical welding, jump welding, and segmented back welding should be preferred. In the welding process of components, in order to achieve effective control of shrinkage deformation, pre-set anti-deformation methods or reserved welding can also be used. The amount of anti-deformation and shrinkage allowance can be determined according to the target test or calculation. In the process of assembling welded components, welding should be carried out in the order of joint shrinkage from large to small, and the joint constraints can be effectively controlled.

4.5 Innovative construction steel structure welding

The building steel structure itself belongs to a new type of building system, which has good seismic performance in actual use. Moreover, this new type of technology meets the needs of ecological development, because the steel structure itself is environmentally friendly, which is an essential component of modern buildings, and will also promote the development and progress of the construction industry to a certain extent.

Therefore, under the influence of this general environment, if the construction industry wants the structure to fully play its role, it must proceed from reality and continuously improve the welding technology of steel structures, thereby fundamentally improving the welding level. With the continuous development and change of the times, the original manual welding and cutting technology has gradually become intelligent. Such a transformation can not only reduce the working pressure of the staff, but also improve its safety and help promote the further development of steel structures. Generally speaking, steel structure welding technology has many advantages, and it can be found in various regions of the country. Future development may only increase, and more stringent requirements are put forward for welding technology in steel structure construction of construction projects. At this stage, the level of domestic welding technology has reached the level of globalization and is at the forefront of the world. Even so, there are still many problems and defects in welding technology. How to better deal with these problems and defects requires the relevant departments of our country and those engaged in Technicians in welding dig deeper.

About Us

About Us 2023-04-12

2023-04-12