Large-span space structure is often an important symbol to measure the level of construction technology of a country or region. Its structural forms mainly include five major space structures such as space frame structure, space shell structure, suspension structure, membrane structure, thin shell structure and various types of combined space structures. Various forms of space structure have been widely used in stadiums, exhibition centers, theaters, large shopping malls, factory workshops and other buildings.

Keywords: large-span space structure, form, feature

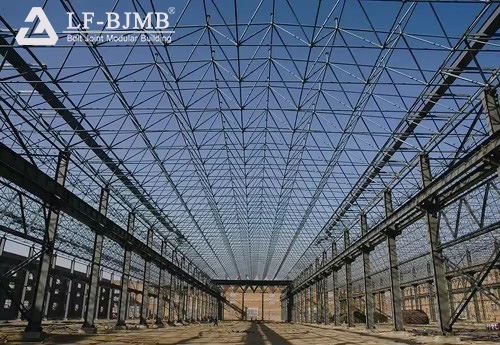

1.Space frame structure

The space structure connected by multiple rods through nodes according to a certain regular geometry is called grid structure, in which the double-layer or multi-layer flat plate-shaped grid structure is called space frame structure. It is usually made of steel pipes or steel sections.

1.1 Forms of space frame structure

(1) Space frame structure composed of plane truss system. Mainly there are: two-way orthogonal orthogonal space frame, two-way diagonal diagonal diagonal space frame, two-way orthogonal diagonal space frame, three-way space frame and other types.

(2) The space frame structure composed of quadrangular cone. Mainly: positive release quadrangular cone space frame, oblique release quadrangular cone space frame, positive release pumping quadrangular cone space frame, checkerboard-shaped quadrangular cone space frame, star-shaped quadrangular cone space frame, one-way folding type space frame and other types.

(3) Triangle cone structure. Mainly: triangular cone space frame, hollow triangular cone space frame (divided into type Ⅰ and Ⅱ type), honeycomb-shaped triangular cone space frame and other types.

(4) Hexagonal cone composed of space frame structure. The main forms are: positive hexagonal cone mesh frame.

1.2 The main features of the space frame structure

Space work, simple force transmission path; light weight, high rigidity, good seismic performance; easy construction and installation; mesh frame rods and nodes are easy to be stereotyped, commercialized, and can be batch-produced in factories, which is conducive to improving the production efficiency; mesh frame is flexible in plane layout, flat roof, which is conducive to the hanging of the ceiling, installation of pipelines and equipments; mesh frame’s architectural shape is lightweight, beautiful, generous, which is convenient for the architectural treatment and decoration.

2.Mesh Shell Structure

Curved mesh structure is called mesh shell structure, and there are single-layer mesh shell and double-layer mesh shell. There are single-layer mesh shell and double-layer mesh shell. The materials used for mesh shell mainly include steel mesh shell, wood mesh shell and reinforced concrete mesh shell.

2.1 The form of mesh shell structure

There are mainly spherical mesh shell, hyperbolic mesh shell, cylindrical mesh shell, hyperbolic parabolic mesh shell and so on.

2.2 Main features of mesh shell structure

The main characteristics of both rod structure and thin shell structure, the rod is relatively single, the force is more reasonable; the rigidity of the structure is large, the spanning capacity is large; can be assembled into a large space with small components, small components and connecting nodes can be prefabricated in the factory; easy to install, do not need large-scale machinery and equipment, the comprehensive economic indicators are better; the modeling of the rich and colorful, regardless of whether it is the plane of the building or the space curved surface shape, according to the requirements of creation. The modeling is colorful and can be selected arbitrarily according to the creative requirements.

3.Membrane structure

Membrane structure, also known as fabric structure, is a new type of large-span space structure developed in the middle of the 20th century. It is made of soft fabric with excellent performance, and the membrane surface is supported by the air pressure inside the membrane, or the flexible steel cable or rigid support structure is used to make the membrane produce a certain pre-tension, so as to form a structural system with a certain degree of rigidity and able to cover a large space.

3.1 Main forms of membrane structure

There are mainly air-supported membrane structure; tensioned membrane structure; skeleton supported membrane structure and other forms.

3.2 Main features of membrane structure

Light self-weight, large span; free and rich architectural modeling; convenient construction; good economy and high safety; good light transmittance and self-knotting; poor durability.

4.Suspension structure

Suspension structure is to be able to pull the cable as the basic load-bearing components, and will be arranged in accordance with certain rules of the cable composed of a class of structural systems, suspension roof structure is usually composed of three parts of the suspension system, roofing system and support system. Most of the steel cables used in the suspension structure are parallel steel wire bundles composed of high-strength steel wires, steel strands or steel cables, etc., and round steel, steel profiles, steel strips or steel plates and other materials can also be used.

4.1 Suspension structure form

Suspension structure according to the direction of the arrangement of the cable and the number of layers are divided into: unidirectional single-layer suspension structure; radial single-layer suspension structure; bidirectional single-layer suspension structure; unidirectional double-layer prestressed suspension structure; radial prestressed suspension structure; bidirectional double-layer prestressed suspension structure; pre-stressed cable network structure and so on.

4.2 Characteristics of suspension structure

Suspension structure force characteristics is only through the axial tension of the rope to resist the role of external loads, the structure does not appear in the bending distance and shear effect, can make full use of the strength of the steel; Suspension structure of a variety of forms, the layout is flexible and can be adapted to a variety of architectural planes; Due to the self-weight of the steel cable is very small, the roof structure is lighter, and the installation does not need a large-scale lifting equipment, but the analysis and design theory of the suspension structure compared with the conventional structure, the Complex, limiting its wide application.

5.Thin shell structure

Shell structure in construction projects are mostly thin shell structure (academically defined as thin shell to meet the t / R ≤ 1/20 shell).

5.1 Forms of thin-shell structures

Thin shell structure can be divided into rotating shell and moving shell according to the formation of curved surface; according to the construction material, it can be divided into reinforced concrete thin shell, brick thin shell, steel thin shell and composite thin shell.

5.2 Characteristics of thin shell structure

Shell structure has very good bearing performance, can withstand considerable loads with a small thickness. The strength and stiffness of the shell structure mainly utilizes the rationality of its geometry, replacing the bending internal force with direct compression of the material, thus giving full play to the potential of the material. Therefore, the shell structure is a kind of high strength, high stiffness, material saving that is economic and reasonable structural form.

In addition to the above space structures, there are several commonly used space structures such as combined space frame structure, prestressed space structure, pipe truss structure, tension beam structure, point-connected glass curtain wall supporting structure, cable dome structure, etc., which have their own characteristics and practical scope. For example, point-connected glass curtain wall supporting structure can utilize the transparent property of glass to pursue the communication and integration of internal and external space of the building, and people can see the whole structural system of supporting glass panels clearly through the glass, which not only plays a supporting role, but also has a strong structural performance function; The rope dome structure fully embodies the idea of “the island of compression rods exists in the ocean of tension rods”, which is a structural system composed of continuous tension ropes and discontinuous compression rods with reasonable force and high structural efficiency.

About Us

About Us 2024-12-04

2024-12-04