1.Classification of roofing materials

Roofing materials for light steel structure should adopt building materials with properties of light weight, high strength, durability, fire resistance, heat preservation, heat insulation, sound insulation, seismic resistance and waterproofing, etc. Meanwhile, it is required to be simple in structure, convenient in construction and capable of industrialized production, such as pressurized steel sheet, space board (light board composed of cement foam core material and cement surface layer), asbestos cement tile and corrugated iron, etc. At present, metal pressurized board, metal pressurized composite heat preservation board and sandwich board are commonly used at home and abroad. At present, it is commonly used at home and abroad are metal compression molding board, metal compression molding composite heat preservation board and sandwich board.

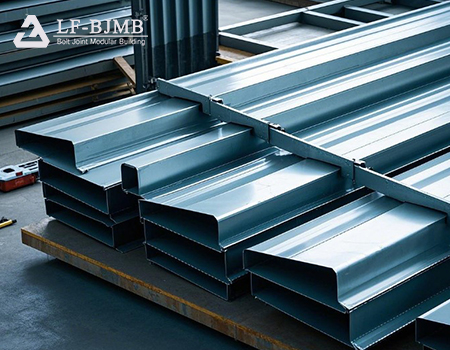

(1) Metal Pressure Plate

Metal pressure plate is the most widely used roofing material in the light roof purlin system. It adopts hot plated steel plate and color plated steel plate, which is rolled and cold-bent into various wave shapes with the features of light weight, high strength, beauty, durability, easy construction, seismic and fire resistance, etc. The self-weight of single-ply plate is 5.5kg, which is the highest in the world. The self-weight of single-layer plate is 5~10kg/m2, while the reinforced concrete structure is 250~300kg/m2, and the brick wall is about 400kg/m2, and its self-weight is 1/20~1/30 of the traditional structure When there is a requirement of heat insulation, double-layer steel plate can be used in the middle of the insulation layer (ultra-fine centrifugal glass fiber cotton or rock wool, etc.) practice. The total weight of the roof is generally not more than 20kg/m2 (including purlin).

At present, the processing and installation of pressed steel plate has reached standardization, factory and assembly, and its maximum permissible purlin distance can be selected according to the type of plate, supporting conditions, load and thickness of the heart plate, and the product specification.

(2) Space plate is a high-strength cement foam process prepared by the artificial light stone as the heart material, glass fiber mesh (or fiber bundles) reinforced upper and lower cement surface layer and steel edge ribs (or concrete edge ribs) composite of the new lightweight roofing panels, with good stiffness, high strength, ductility and other characteristics, it has a good structural performance and engineering applications of the future. Its self-weight of 0.45 ~ 0.85KN / m2, all roof load standard value (including live load) generally does not exceed 1.5 KN / m2.

Space plate can be determined according to the space frame of the grid to determine its plane size. When installing, the corner of the space plate is welded directly with the support of the space frame, and generally there is no need to set up another purlin, and there is a 10mm assembly seam between the plate and the plate, and it is recommended to use waterproof grease for the embedded seam. Space plate can be directly laid on the waterproofing membrane, without the need for another insulation layer and leveling layer, waterproofing membrane should use rubber-plastic waterproofing membrane.The common sizes of space board are 3mx3m, 1.5mx6m, 3mx6m, etc.

(3) Asbestos cement tiles

Asbestos cement tiles, with a weight of 0.2 KN/m2, is a traditional building material, characterized by light weight, beautiful appearance and easy construction. In addition to being used as roofing material for industrial and civil buildings, it can also be used as wall enclosure material. The material properties of asbestos tiles have such defects as high brittleness, easy cracking and breaking, shrinkage and cracking due to water absorption, and flexural deformation. At present, China’s asbestos tile production is not much, the quality is not high enough, but also need to actively study and take measures to improve the quality. Some projects under the asbestos tiles with wooden lookout boards or the use of reinforced asbestos-cement corrugated tiles in order to improve their use and facilitate the inspection and maintenance.

(4) Corrugated iron

Corrugated iron, with a weight of 0.05 KN/m2, is a traditional building material characterized by light weight, beautiful appearance and easy construction, but the specifications of the tiles have not yet been finalized, and most of the products used in the project are self-pressing products.

(5) Aerated concrete roof panel

Aerated Concrete Roofing Panel with a dead weight of 0.75~1.0 KN/m2 is a kind of lightweight porous panel with load-bearing, heat preservation and structural integration. It is made of cement (or fly ash), slag, sand and aluminum powder as raw materials, which is ground, batched, poured, cut and autoclaved and maintained, and it has the advantages of light weight, good heat preservation, good acoustic absorption, etc. Because of the mechanized production, the board has the characteristics of lightweight, good heat preservation and sound absorption. Because of the system of mechanized production, the size of the board is accurate, the surface is flat, generally can be directly on the board laying coil waterproofing, construction is convenient.

2.Common roof slope selection

(1) Architectural requirements: roof slope, favorable drainage. However, the roof slope is too large, the flow rate increases, encounter obstacles will produce splash water and lead to roof leakage. Roof slope is too small, slow drainage, the length of the roof should not have a long direction lap joints, and need to increase the wave height of the pressure plate. In addition, the roof slope is too small, easy to produce water, accelerate the corrosion of the pressure plate, affecting the service life, but also prone to poor drainage, roof leakage, roof waterproofing needs special treatment.

(2) Economic requirements: small roof slope, can save roofing materials. Roof slope is too large, not only the roofing material consumption is too much, wall material consumption also increased, this situation is very obvious in the single slope length is large.

(3) Requirements of plate type: The roof slope is closely related to the plate type of roofing compression plate used, and different plate types have different requirements for the minimum slope.

(4) Construction requirements: the roof slope is too large to bring difficulties in construction and installation. According to the construction unit reflects, the roof slope, construction personnel walking has been difficult. 1/3 of the roof slope, construction personnel walking is very difficult, can only step on the roof exposed bolt head walking, often many exposed bolt head step tilt, affecting the construction quality.

(5) The advantages of using a smaller roof slope:

Reduce the wind area of the mountain wall, reduce the section and length of the wind column.

It can reduce the amount of wall beams on the mountain wall.

Reduce the area of roof panel.

It can reduce the area of wall panel.

Slope of 2%, which visually makes people think that it is almost flat, and is conducive to the realization of the effect of flat roofing of the building without increasing the cost.

The slope of the roof can reduce the indoor space, reduce the heat loss and save the heating cost.

About Us

About Us 2025-01-01

2025-01-01