Glass lighting roof has a strong artistic expression and visual impact, such as the famous French Louvre “glass pyramid”, the Shanghai Oriental Art Center “Butterfly Orchid”, with the shape of light, lighting efficiency and many other advantages. However, the construction of shaped glass lighting roof requires high precision and difficulty, if the construction is not appropriate, it will lead to glass burst, water leakage, light insulation efficiency and other problems, and even bring serious impact on the valuable indoor facilities. Therefore, the study of the construction technology of the light roof of large public buildings is an important measure to ensure its quality and durable life.

1 Project Overview

As an important part of the peninsula blue economic development strategy, an ecological park is located in Huangdao District, Qingdao City, with a planning area of 10km2, which has just been awarded the title of “National Green Ecological Demonstration City (Low Carbon Ecological Pilot Town)” by the Ministry of Housing and Urban-Rural Development. The Eco Park Experience Center is the first project completed in the park. The total height of the structure is 12.0m, and the roof structure is in the form of space invisible steel frame + high insulation light roof, the light roof façade is a diamond-shaped irregular multi-faceted prism, the plane is irregular trapezoid, the north-south direction is 36.1m long, the east-west length is 29.6m, as shown in Figure 1. The local part is 18.75kW distributed photovoltaic roof. The experience center adopts more than 20 green building energy-saving technologies, such as thin-film photovoltaic, intelligent lighting, ground-source heat pump, bionic ventilation, and high-insulation vacuum glass.

FIG. 1 Effect of lighting roof

2 Main construction process

To ensure the installation quality of the light roof, precision control is the primary task

2.1 Four-dimensional positioning of the steel roof frame

Comprehensive construction site conditions and economic indicators of the project, the steel roof frame components on-site processing, four-dimensional positioning and installation technology was adopted. Since the position of the round steel pipe members of the roof frame is not in the same plane, CAD software is used for three-dimensional construction design, and the steel structure installation tire frame and member positioning are considered in an integrated manner, and a high-precision total station is used to guide the plane position of the steel members marked on the ground to the end of the tower, and after the positioning tire frame is installed, the elevation of the members is guided, and then the axial offset angle of the members is controlled to achieve the four-dimensional control purpose. The technology is extremely effective in controlling the width of the weld seam of complex curved surfaces, the accuracy of steel pipe butt and weld seam occlusion, greatly improving the installation accuracy and welding quality of steel structures.

3.2 Glass secondary intelligent layout design and splicing correction technology

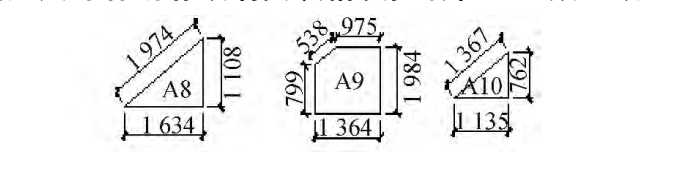

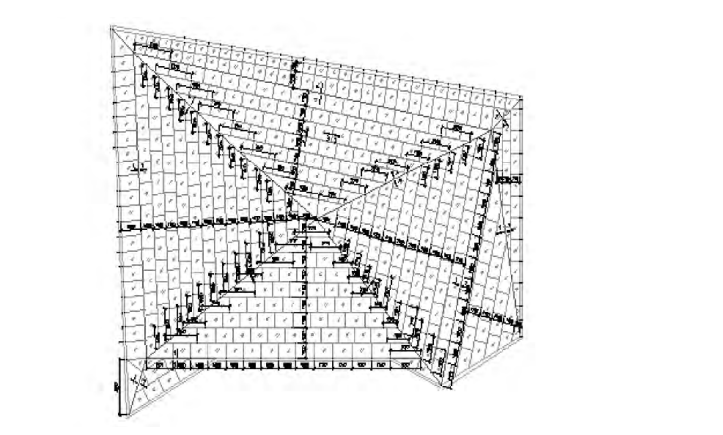

The high insulation lighting roof of this project is nine-sided with nearly 200 glass sizes, and the vacuum glass has 4 glass layers and 1 vacuum layer, which is difficult to make and install. Through secondary intelligent layout design, the three-dimensional roof space dimensions are converted into nine two-dimensional plane dimensions, and then the lengths of each side of various glass axes are determined by the two-dimensional dimensions as the underlayment dimensions, as shown in Figure 2. Then, according to the length of each side of each piece of glass and the seam width requirements, the two-dimensional planar assembly surface is composed, and returned to the three-dimensional roof for inspection and correction by computer CAD, as shown in Figure 3. This method can control the accuracy of all glass installation to the order of mm.

Figure 2. Cutting size of insulating glass

Figure 3 Space dimension of insulating glass

About Us

About Us 2023-08-02

2023-08-02