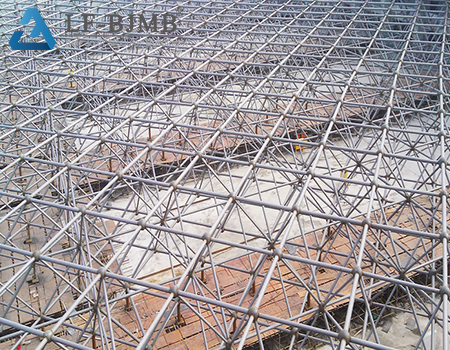

1.Foundation review → Classification of space frame components → Installation of space frame → Painting of space frame

2.Installation Process and Construction Preparation of Bolted Ball Space Frame:

(1) Semi-finished products such as rods, bolts, welding rods and supports for steel space framerack installation should meet the design requirements and relevant national standards, and be classified and stacked neatly so that they can be extracted in pieces during the installation process of bolted ball space frame rack company.

(2) Check the concrete strength at the top of the column, double-check the center point of the embedded bearing at the top of the reinforced concrete column, the elevation difference and the spacing of adjacent bearings, and make sure that the axis and elevation of the embedded steel plate are in accordance with the relevant regulations.

(3) Bolt ball space frame company lifting machinery and equipment selection of 2 sets of 50 tons of car crane, welding machine, steel tape measure, calipers, level, latitude and longitude, wrenches, temporary support, screw jacks, inverted chain and other tools are fully prepared.

(4) Bolt ball space frame company measure and set the line, arrange the position and elevation of each pivot point.

3.Quality Control Measures for Assembling.

(1) When installing and positioning the steel space frame, the bolted ball space frame company will cross the auxiliary line on the surface of the support transition plate and embedded parts respectively.

(2) When assembling the local lifting unit steel space frame, take the quadrangular cone as the unit to assemble sequentially until the lifting unit space frame installation is completed; the bolt ball space frame company adjusts while installing, so that the cross line of the bearing transition plate coincides with the cross line of the pre-embedded parts, and quickly weld the support after the adjustment is completed.

(3) Other axis of small vertebrae space shell required materials transported to the installation position, in turn, the assembly of the upper chord, the lower chord of small cones, in accordance with the order of assembly in order to install, until the space shell installation is complete.

(4) When local lifting assembles 3~4 axes steel space frame, in order to control the deflection of steel space frame and prevent the displacement of steel space frame, steel wire rope is set up at the node of lower chord of space frame to pull it and inverted chain is adopted to assist in the adjustment.

(5) In the process of assembling, the elevation of the lower chord of the steel space frame is monitored in real time to avoid cumulative errors, and jacks, inverted chains, latitudinal and longitudinal instruments, total stations, leveling instruments, steel rulers and other tools are used for real-time correction of deviation.

About Us

About Us 2025-01-20

2025-01-20