3.3 Installation process method

After careful study of the design drawings and repeated comparisons of several installation schemes, from the aspects of economy, safety and construction quality control, a full hall of scaffolding is used as the construction platform for installation and construction. This scheme has high reliability and can ensure the quality of the project.

3.4 Installation preparation

Since there are many space frame units and various types of components, they must be stacked in pieces according to the units, so as to facilitate the installation and extraction of materials.

3.5 Assembly sequence

3.5.1 General idea of construction

Since the steel space frame structure of this project is a spiral ball space frame, the construction premise of the steel space frame is that the steel structures of the 2-23 axis and the 24-32 axis on both sides have been installed before the construction can be started.

3.5.2 Space frame installation

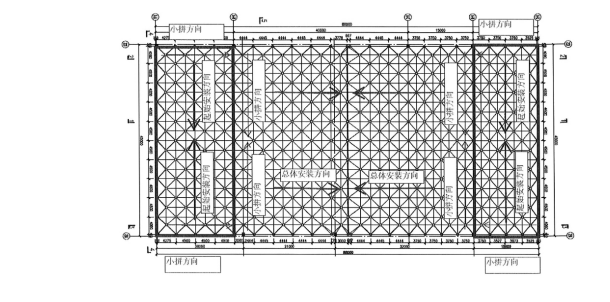

In order to improve the installation accuracy and reduce the error, the installation starts from the A and E axes, and the two sides are respectively installed towards the middle, and adjusted to the normal installation direction after starting the head. See Figure 2 below for the installation sequence .

Figure 2 Steel space frame Installation Sequence

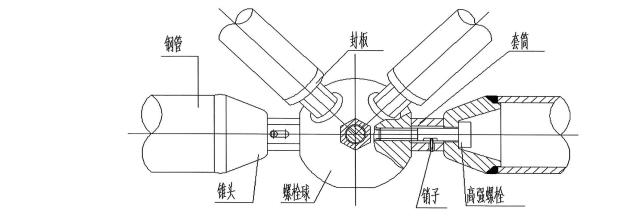

The space frame node connections are as shown in Figure 3 .

Figure 3 Space frame node connection

3.5.3 Assembly process

(1)When installing and positioning the space frame, draw a cross auxiliary line on the steel column corbel.

(2)All space frame components need to be transported to the scaffold for assembly. In order to prevent too much material on the scaffold, the materials transported to the scaffold each time shall not exceed one assembly batch, and shall be dispersed in time .

(3)The space frame node is the key stress-bearing part, and the high-strength bolts in the installation are screwed into the bolts along with the assembly.

In the ball, make it tightly combined with the sleeve. After the high-strength bolt is in place, screw the set screw into the deep groove.

(4)In order to control the deflection of the space frame and prevent the instability of the space frame during the installation process, set up temporary supports at the lower rotation nodes of the space frame, and use jacks or adjustable supports to assist in adjustment.

(5)During the installation process, track and control the downswing elevation of the space frame at any time, find the accumulation of errors, and correct the deviation in time. The deviation correction method can be carried out with tools such as jacks, chains, theodolites, total stations, levels, and steel rulers.

(6)The temporary support and jacks supporting the space frame can only be removed after the installation of the unit in the space frame is completed and a comprehensive inspection is carried out. When removing the support, it is necessary to control the simultaneous removal to avoid the space frame at the fulcrum due to the force of individual fulcrums. The rod deforms too much and is destroyed.

3.5.4 Quality Control Standards

(1)The allowable deviation of the small unit : the diagonal length deviation of the upper chord member is ±3.0mm . the node center offset is 2.0mm. the length of the chord is ±2mm. the height of the cone is ±2mm. the deviation of the bending sagittal height of the rod axis is L1 /1000 is not greater than 5mm (L1 : rod length) .

(2)The allowable deviation of the steel space frame installation is : the longitudinal and transverse lengths are ±L/2000 (±30.0mm), the height difference between adjacent supports is L/400 and not greater than 15.0mm, and the maximum height difference is not greater than 30.0 mm(L : span length).

(3)After the installation of the steel space frame and the roofing project are completed, measure the deflection value respectively, and the deflection value is ≤ 1.15 times the design value.

3.5.5 Paint touch-up

After the installation of the steel space frame, due to the transportation of the rods and the installation process, there will always be partial surface paint peeling off between the rods and the lifting tools. The surface of the components must be cleaned before repainting. Before the platform is dismantled, To finish all the repainting work of surface paint falling off, the paint material used should be consistent with the color performance of the original design, and it should be carried out sequentially from beginning to end when repainting on the same space frame, so as to avoid contamination of painted components due to workers walking.

3.5.6 Space frame acceptance

According to the space frame acceptance specification and design requirements, 15 days after the installation of the purlins and roof system on the upper part of the space frame, the proprietor, the design, consulting and construction unit jointly carry out the settlement of the 14 points designated by the consultation twice in a row every 15 days Observation of disturbance data. It can be seen from the observation data in the table that the minimum value of deflection settlement deformation is 38mm, and the maximum value is 47mm, which is much smaller than the design value of the maximum allowable deflection of 180mm, indicating that the space frame as a whole is stable and firm.

3.5.7 Precautions

(1)After the installation of the steel space frame, attention should be paid to the synchronization and gradual disassembly when removing the temporary support, so as to prevent the stress concentration from causing local deformation of the space frame, or deforming the local space frame.

(2)After the space frame is installed, the finished space frame should be protected, and objects should not be piled up on the top of the space frame, especially when purlins and roof panels are installed, they should be scattered and stacked without overloading, and should be handled with care. It is strictly forbidden to hit the space frame rods to deform the rods.

About Us

About Us 2024-08-23

2024-08-23