1 Project Overview

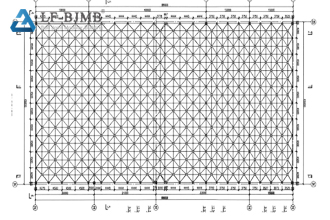

The project area of Malaysia CSR plant is tropical rain forest climate, with more rain and hot climate all year round. The plant mainly consists of assembly workshop and transfer frame workshop, the total length of the plant is 418.6m, the maximum width is 88m, the maximum height is 23.5m, the plant covers large-scale steel structure, steel truss, steel space frame and auxiliary rooms. The maximum span of steel truss is 40m, the maximum span of steel space frame is 45m, the width is 88m, the height is 19.6m, the projected area is 3960m2, the structure of steel space frame is square quadrangular conical flat plate, the node adopts bolted ball node, the mesh specification is 4.5m×4.5m, and the form of support is multi-point column chordal ball support.

2 Project characteristics and difficulties

2.1 Project Characteristics

2.1.1 Large engineering column spacing

The projected area of each single unit of this engineering space frame project is different, as a flat plate structure, the maximum column spacing of 45m already belongs to the large column spacing.

2.1.2 High volume of steel space frame fabrication and installation work

This project has a large volume of production and installation works, geometric dimensions, a variety of quantities, high installation accuracy requirements, transport and installation difficulties. Because all kinds of steel components need to be processed and made in the factory, and then transported to the construction site for installation through domestic transport, all kinds of components must be organised and planned in accordance with the requirements of the drawings, classification production, numbering, packing.

2.2 Engineering Difficulties

Due to the large column spacing in this project, the stiffness, stability, deflection, and internal forces of the members during assembly and collocation need to be calculated for construction, and reinforcement measures need to be taken if necessary.

Due to the tight schedule of the project, a reasonable installation method under the premise of ensuring quality and safety is one of the difficulties of this project. For the installation of steel space frame in this project, it is necessary to carry out working condition calculation according to the installation plan, so as to meet the working condition internal force after removing the temporary support close to the design internal force of the steel space frame at that stage. Controlling the deflection under the steel space frame is one of the difficulties in this project. Due to the relatively large number of component types and cross-section sizes, it requires precise organisation of construction organisation, factory production scheduling, component transport scheduling, etc. to coordinate production and ensure smooth installation at the site. As the construction site is a multi-work cross operation, the site construction must coordinate with each other, reasonably arrange the installation equipment, reasonably use the existing components, try to reduce the auxiliary work and shorten the construction period as much as possible, in order to ensure the precise assembly and correct positioning of the whole steel structure project, it is necessary to organise a special person to be responsible for the inspection of the workpieces and the positioning measurements and corrections, and to be prepared for it in terms of manpower and material resources.

3 Construction Deployment

The construction layout is shown in Figure 1.

Figure 1 General construction layout

3.1 Steel space frame construction and installation process

Steel space frame construction and installation process: foundation review → space frame components classification → space frame installation.

3.2 Construction preparation

In order to ensure that the installation is carried out in a smooth and orderly manner, the space frame should be fully prepared before construction.

(1) Check the bolts, rods and semi-finished products for the installation of the steel space frame, which should be in accordance with the design requirements and the corresponding international standards, and should have the factory certificate of conformity.

(2) Construction tools such as welding machine, steel tape measure, caliper, level, latitude and longitude, spanner, temporary support, screw jack, guide chain, etc. should be fully prepared.

(3) Do a good job of measurement, before the installation of the space frame axis and elevation should be checked line checking. Space frame axis, elevation position must comply with the design requirements and the provisions of the relevant standards, measurement and placement of the position and elevation of the pivot point to ensure the construction quality of the space frame structure.

About Us

About Us 2024-07-22

2024-07-22