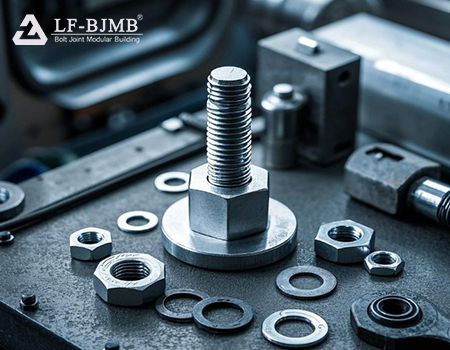

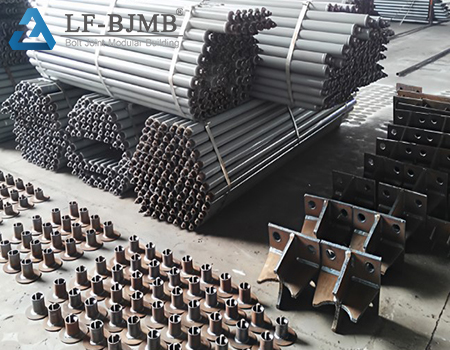

The space frame structure mainly consists of steel pipes, high strength bolts, steel balls, cones, ribless nuts, bearings, supports and their connectors. The quality of each part of the material has a vital influence on the stability of the space frame structure.

How to choose the main materials in the space frame structure

1.Steel pipe: choose Q235B steel in GB700. Its quality should be in line with the current national standard “carbon structural steel” GB700-88, and should have tensile strength, elongation, yield strength (or yield point) and sulfur, phosphorus, carbon content and cold bending test qualification guarantee. space frame structuresteel pipe should be strictly in accordance with the number of steel, welding, painting and inspection.

2.High-strength bolts: For high-strength large hexagonal bolts for steel structure, it should be in accordance with GB1228-91 10.9 grade. Conform to the provisions of GB / T16939 “wire mesh bolts and ball and socket joints with high-strength bolts”. Select 40Cr in GB3077, the finished product does not allow any part to have quenching cracks in any depth or length. Surface strength up to HRC32-36. threads should be in line with the general thread tolerance and fit in GB 6 of 6g. surface should be blackened and coated with anti-rust oil.

3.Steel ball: bolt ball selected from “carbon structural steel technical conditions” GB699 No. 45 steel.

4.Cone head: choose Q235B steel forging.

5.Unthreaded nut: Q235B steel forgings, when the high strength hole > 30, the 45th steel forgings.

6.Support: support and connecting parts are made of Q235B steel.

The above materials are factory-processed products and should be selected with the reputation of space frame structure and accessory manufacturers, and the space frame structure construction site can be completed by only assembling, lifting, welding, and surface treatment of the above materials.

For space frame structure companies, it is very important to have a professional space frame structure installation and processing, which will bring advantages in terms of quality and aspect. For the characteristics of space frame structure processing, the space frame structure itself is lightweight, strong and has a small footprint. In the installation process, manual combination is required, without the need for professional personnel to carry out construction operations, the installation is very convenient.

The space frame structure project has a wide range of applications, good ventilation conditions and is easy to dismantle. At the same time, it has a strong span. Usually, the structure of the space frame structure can be seen in the construction of stadiums and factory buildings. It is a relatively practical construction. Profiles, high strength, compression resistance and wind resistance have been well used in space frame structure engineering.

Generally speaking, the splicing method is generally adopted as integral splicing method, integral splicing method and lifting method. For power space frame structure companies, different splicing methods should be used according to the construction requirements of the project, and the effect is very obvious.

About Us

About Us 2025-01-17

2025-01-17