In steel structures, the choice of welded or bolted ball nodes requires several factors to be considered, including the force characteristics of the structure, construction conditions, cost budget, and maintenance requirements. The following are some suggestions on the selection of these two types of nodes:

Structural Force Characterization:

Welded Ball Nodes: Welded ball nodes usually have better integrity and stiffness, and can resist larger bending moments and shear forces. Therefore, welded ball nodes may be more suitable in structures that need to withstand large loads or have complex force conditions.

Bolted ball nodes: Bolted ball nodes have a certain degree of rotation, closer to semi-rigid nodes. In structures that need to allow for some degree of relative rotation or deformation, bolted ball nodes may be more appropriate.

Construction Conditions:

Welded ball nodes: The construction of welded ball nodes requires welding operations on site, so welding equipment, welding technology site environment, and other factors need to be taken into account. In addition, the welding process may produce a heat-affected zone, which has a certain impact on the material properties and needs to take appropriate measures to control.

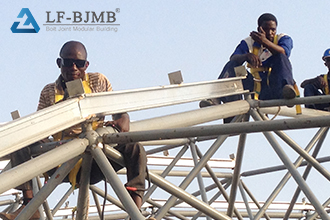

Bolted ball node: the installation of a bolted ball node is relatively easy, most of the work can be completed in the factory prefabrication, and the site only needs to be bolted. This node form is suitable for rapid installation and dismantling occasions, especially in the need for frequent replacement or adjustment of the structure of the project.

Cost budgeting:

The cost of welded and bolted ball nodes varies depending on factors such as materials, machining, and installation. In general, bolted ball nodes may cost slightly more than welded ball nodes because the manufacturing process is more complex and requires more parts and precise machining. However, when considering cost, factors such as construction lead time, maintenance costs, and long-term utilization benefits should also be taken into account.

Maintenance requirements:

Welded ball nodes: Welds in welded ball nodes require periodic inspection and maintenance to ensure their integrity and reliability. Problems such as corrosion and cracks in the welds may need to be dealt with promptly.

Bolted Ball Nodes: The maintenance of bolted ball nodes is relatively simple, with the main focus on the tightening status of the bolts and anti-loosening measures. Regular inspection and adjustment of bolt preload can ensure the stability and safety of the node.

To summarize, when choosing between welded ball nodes or bolted ball nodes, several factors such as the stress characteristics of the structure, construction conditions, cost budget, and maintenance requirements need to be considered. It is recommended to consult professional structural engineers or experts in related fields in the actual project to get more accurate and specific suggestions.

About Us

About Us 2024-05-22

2024-05-22