With the continuous improvement of the design, manufacture, and construction technology of the large-span dome space frame storage shed, the cost is continuously reduced, and the domestic and foreign requirements for environmental protection are getting higher and higher. more, So how do you build a dome roof? Let’s look at the dome roof’s construction process through an example.

1. Dome roof project overview

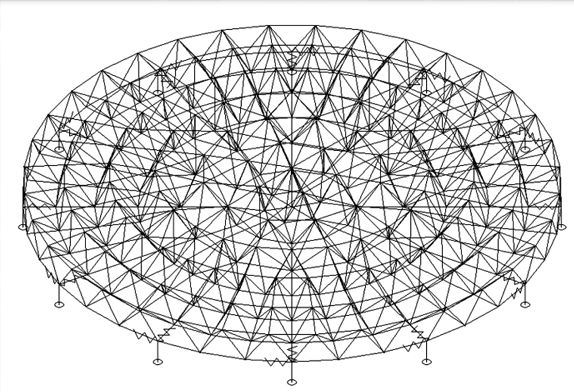

The coal storage bunker is a space frame dome shed, with a diameter of 133m, a height of 67m, a surface area of 28200m2, 36 supports, the top elevation of the supports is 18.6m, the thickness of the lattice shell is 2m, the lower part is a reinforced concrete retaining wall, and the amount of steel used is more than 700 tons (Fig. 1).

Fig. 1 1.2 million tons of storage bunker dome shed under construction

2. Construction of the space frame dome roof

The common installation method of bolted ball joint space frame is the high-altitude bulk method of full-scale scaffolding. This construction method is simple in process, easy to master, does not require large lifting equipment, and does not require high site conditions and installers, so it has been adopted by most space frame installation projects, but this method is not applicable to this project. reason:

- Scaffolding takes a long time and is labor-intensive, which affects the progress of the entire project;

- High cost of leasing, erecting, and dismantling scaffolding;

- The installation of the space frame dome roof is carried out at the same time as the installation of the equipment, and the erection of scaffolding will affect the installation of the equipment.

After many times of communication and research, it was decided that the block installation method and the micro spreader high-altitude bulk method should be adopted. The program is carried out in two phases. The first stage is the installation method of strips and blocks. According to the installation height, mechanical performance of lifting equipment, construction site conditions, space frame division, and other factors, the space frame is divided into several blocks, which are first assembled on the ground, and then hoisted into blocks. The design position is temporarily fixed and then the connection and adjustment between the bars are carried out. This item is generally 6 grids in the horizontal direction and 2 grids in the vertical direction as a bar. The second stage is the high-altitude bulk method of the micro spreader, that is, the space frame is first assembled into small units on the ground, and the crane or the micro spreader installed on the grid frame is used to hoist it to the design position, and the connection of the nodes is completed by the aerial workers. When the project is hoisted with a crane, 2 bolt balls and 8 rods are used as a small unit; when a micro spreader is used for hoisting, due to the limited lifting force, a bolt ball and 4 rods are used as a small unit. The practice has proved that the method is economical, practical, convenient, and quick. Since a lot of work is done on the ground, there are fewer safety hazards, and good economic and social benefits have been achieved.

3. Control of the dome roof installation accuracy

The accuracy requirements of space frame installation are very strict. If the installation error is too large, it will directly affect the installation speed, and at the same time, large stress will be formed inside the structure, which will affect the safety of the structure. To control the installation accuracy and prevent the accumulation of errors, two steps must be done: first, the first-round installation includes the control of the elevation of the bearing and the control of the roundness after closing. The height of the bearing is adjusted by steel plates of different thicknesses, and the roundness control is adjusted by a well-shaped frame and a jack. After repeated adjustment, after the installation error meets the specification requirements, the support is initially welded and fixed. Second, close the loop by loop and review it in time to ensure the overall stiffness of the spherical shell and reduce the accumulation of errors. After the installation of the second and third circles of the space frame is completed, the roundness and closing error of the overall installation should be checked and adjusted in time. After each index meets the requirements, it should be welded and fixed. In the future, it should be installed and closed the circle by circle, and the roundness of the structure should be checked and adjusted after every 3 circles. The adjustment method is to set the ground anchor with wire rope tension.

4. ball panel installation

In order to reduce the number of joints, improve the wind resistance, and beautify the overall effect, the project uses 8-12m long slabs. Since there is very little wind or breeze at the construction site, the veneer is very easy to float under the action of wind during installation. causing an accident. In order to solve this problem, a complete set of installation techniques for veneers under windy conditions have been explored, such as: first the lower layer, then the upper layer, the windward side first, the leeward side first, and the addition of windproof ropes, etc., to ensure the normal installation of the project under general wind conditions.

The installation technology adopted in the steel structure project of the space dome of the 1.2 million t coal storage shed accelerates the installation speed and ensures the quality of installation. It is an optimal balance point in terms of safety, applicability, and economy. It has created better economic benefits and accumulated valuable experience for the construction of larger and more complex space dome projects in the future.

So now you know anything about building a dome roof with space frame, For more information, please feel free to contact us!!!!

About Us

About Us 2022-07-18

2022-07-18