Are open bulk storage systems a thing of the past? With an increasing need for environmental compliance, uncovered stockpiles need to be enclosed sooner rather than later. It’s no surprise that mines, ports, power, and cement plants seek a bulk cement storage system that avoids downtime and high cost. Yet many face additional hurdles, such as:

•Location is remote and rugged with a sloping terrain

•Climate is adverse with a weather window

•Stockpile is an irregular shape

•Site is in a confined area

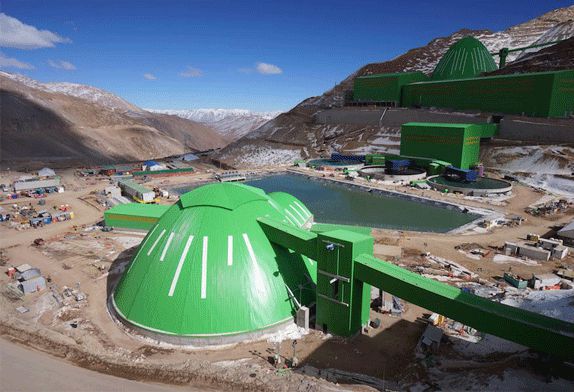

All Purpose, All Terrain

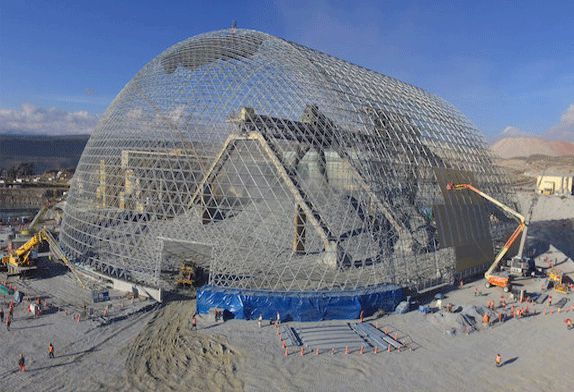

It takes more than conventional building construction to overcome all obstacles. Traditional building solutions with joists, for example, are limited to planar trusses in an array and work in only one direction on level ground. Solutions with machined joints, such as ball-joint systems, are expensive and must minimize the number of nodes.

Custom Design

This technology evolved from space frame shell innovations originally developed by our forefathers in the 1960s. Today, our domes can be designed with a non-circular plan in varying curvatures for complete design freedom. This unmatched, refined, and updated expertise, now covers some of the world’s largest stockpiles.

There is literally an infinite number of possible design plans for a Free-dome structure. For instance, just like our circular domes, Free-domes may have lamella, Hewitt or combination patterns with a single or double structural layer. Once the geometry and support requirements are defined. Whether rock fill, sand, clay, gravel, bauxite, coal or mineral ore, all of the designs can accommodate existing operations seamlessly. Clearances needed for vehicles or equipment, personnel access, and maintenance requirements are readily accommodated during our design work.

Environmental Footprint

Planet-friendly Free-domes have transformed bulk materials handling in rain forests, ports, coastal strips, gravel plains, sandy deserts, high dunes, mountains and salt flats. These clear-span superstructures make full use of space and protect bulk materials from the elements and the surrounding environment from the stockpiles, helping the industry secure a smaller environmental footprint. Extra operational efficiencies and benefits include:

- Fugitive dust, runoff, and noise

- Translucent paneling provides natural interior light

- Structure components are packed into recyclable, metal containers

- No special equipment is required on site

- Locally-sourced labor installs our structures

Zero Downtime

Excellent strength-to-weight ratios make this kind of dome the go-to solution for storing bulk materials, especially in the most challenging locales worldwide. And, we understand that many stockpiles must remain in operation while being covered too.

Our mission is to provide customized storage solutions to industries around the world. To learn more, please complete our inquiry form and let’s get started.

About Us

About Us 2020-12-23

2020-12-23