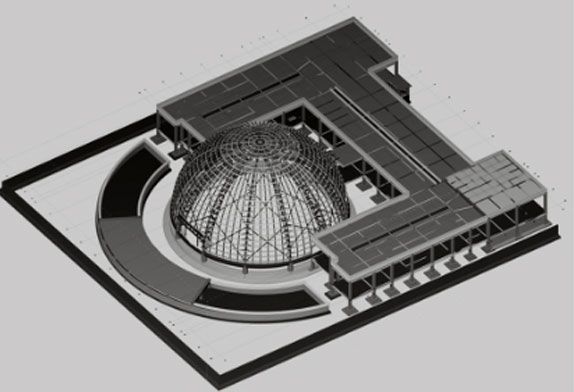

The Taizhong Rail Transit Laboratory project is divided into three parts: the experimental area, the enterprise exhibition hall, and the square. The corporate showroom is located at the heart of the project. The foundation is a concrete ring beam foundation, the upper main structure adopts a hemispherical rib-shaped dome steel frame structure, the main steel frame is a hot-rolled H-beam, 12 axes (30° equally divided), and a span of 36m, which is more dangerous than a certain scale. project. The material is Q235B, the main steel frame is about 6t, the building height is ±18.31m, and the engineering volume is about 180t. The overall structure is mainly connected by high-strength bolts. The building area is about 1050m², and the peripheral structure adopts the grid structure of square tubes. The rectangular square tube purlins are attached to the spherical purlins with a total of 23 floors and 72 longitudinal purlins. The 23 horizontal purlins are concentric rings (different radii), the 72 longitudinal purlins are evenly distributed at 5° (same circle radius), and are surrounded by titanium-zinc plates and glass curtain walls.

Exhibition Hall Dome Steel Structure

The project has the following difficulties: tight construction period; no construction cases to refer to; the construction site is small, with few available vacant land, there is a problem of competing with the civil construction site, and only one gate allows people to enter; the civil construction concrete structure and the steel structure cross construction Condition; there are green trees and lawns around which need to be protected.

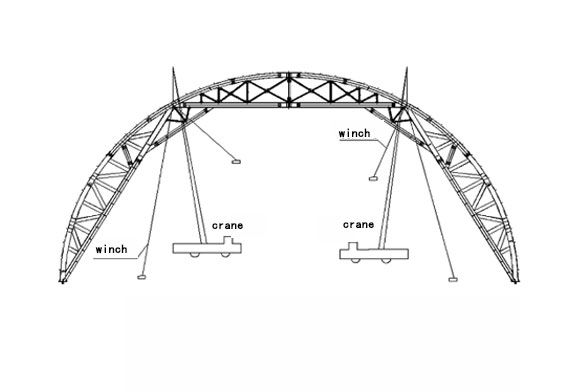

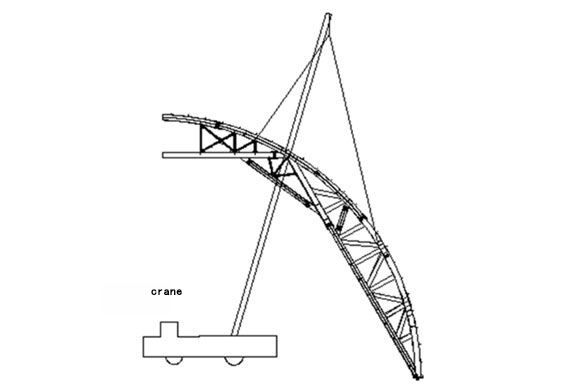

First, the steel frames at the 1-5 axis and 1-11 axis positions are assembled on the ground, and two 25t cranes and two 16t cranes are used to complete the hoisting task of the first and second combined steel frames to form a cross support. The remaining single-frame steel frame is installed with a single 25t crane for hoisting until the main structure construction task is completed. See Figures 2 and 3 for details.

Steel frame lifting

Construction process steel structure production process: Tekla Structures detailed design → material preparation, ordering → raw material (steel, welding consumables, connection fasteners, etc.) inspection → main steel simmering and bending → nesting, splicing → lofting and numbering → cutting, cutting → hole making → component assembly → welding → rust removal, oil brushing → component pre-assembly → component number, acceptance → delivery. Steel structure installation process: component inspection → foundation review, intermediate handover and bottom surface treatment → 1-5, 1-11 axis whole steel frame assembly → rest single steel frame assembly → 1-5, 1-11 axis whole steel frame Hoisting → 1-8, 1-2 axis single jib hoisting → remaining single jib hoisting → support installation → square tube purlin installation → corner brace installation → paint touch up → fire-resistant paint painting.

About Us

About Us 2023-02-08

2023-02-08