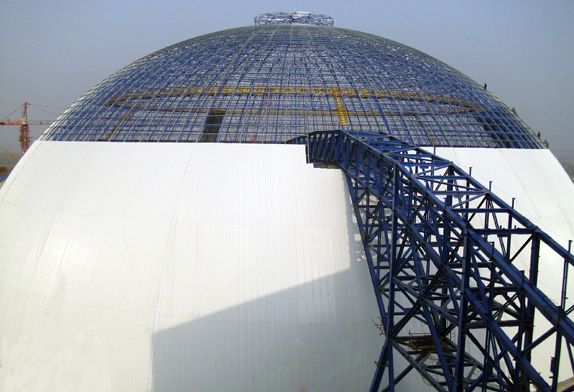

Common closed coal storage sheds structures are: dome coal storage shed, coal storage silo, barrel space frame closed strip coal storage shed, and spherical coal sheds.

Dome storage shed is a non-fully enclosed structure , has a small floor space, fully up to date with reclaiming equipment, a high system reliability, high degree of automation, and high structural safety. Fire protection facilities such as fire blisters are set up around the coal bunker. The space around the equipment is large, and easy to maintain. It has good air tightness and basically does not leak dust. However, the coal filling factor in the coal yard is small, and the effective utilization rate of the coal yard volume is low.

The Dome storage shed can meet the exact proportion of coal blending requirements for multi-coal power plants. It covers a small area and has the highest effective utilization of coal yard volume. The upper part of the silo is provided with a warehouse top distributor, while the lower part is provided with an activated coal feeder as a feeding device, which has high system reliability and environmental protection. There is no effective coal combustion work, small space around the equipment, large amount of equipment maintenance, and high cost.

The structure has high security, good tightness, basically does not leak dust, good environmental protection conditions, beautiful appearance, simple construction and low cost. However, the floor space is large; a bucket wheel turbine is required for each coal yard, and the degree of automation is low. The coal yard is regularly burned, the actual coal storage area is small, and the coal bunker area ratio is low.

About Us

About Us 2020-11-26

2020-11-26