The flat space frame belongs to the space member system, so there are many members on the nodes. The quality of the node structure will directly affect the working performance, installation quality, and soil engineering cost of the space frame. The design requirements of space frame nodes are reliable operation, simple structure, convenient processing and installation, and saving steel. There are many types of joints, such as plate joints, hemispherical joints, spherical joints, circular joints, etc. At present, the most commonly used ones in my country are welded hollow spherical joints and bolted spherical joints.

welded hollow ball joint and bolted ball joint

1. welded hollow ball joint

welded hollow ball joint

When welding hollow spherical joints, two round steel plates are hot-pressed or cold-pressed into two hemispherical shells, and then butt welded. It has been applied to various space frames using steel pipe rods. Its advantages are: that the sphere has no direction, and can be connected with rods in any direction. The steel pipe is cut perpendicular to its own axis, and it is naturally centered when it is connected to the hollow ball node, without eccentricity, and the node force is clear. There are two types of welded hollow ball joints: ribbed and small ribbed. The diameter of the ball is first determined by the structure, and the gap between the rods connected to the joint should be less than 20mm. At the same time, in order to reduce the specifications of ball joints, one or two kinds of hollow balls should be used in a space frame. The thickness of the ball wall can be taken as 1/30 to 1/45 of the diameter, and the ratio of the wall thickness of the ball to the maximum wall thickness of the connected steel pipe is required to be 1.2 to 2.

When the sphere is compressed, if the sphere wall is thin, it will locally destabilize and fail. When under tension, it may be damaged along the connection weld between the steel pipe and the ball wall. If the ball wall is too thin, the ball wall may be damaged by punching. In order to improve the bearing capacity of the hollow ball joint, when the outer diameter of the hollow ball is equal to or greater than 300mm and the internal force of the rod is large, a stiffening rib can be installed in the ball, and the rib can be located in the plane of the main tie rod. The stiffener is a ring, welded to the inner wall of the hollow sphere, and the thickness of the rib should be less than the thickness of the sphere wall. The disadvantage of the hollow ball joint is that stamping and welding cost soil. The hemisphere needs to cut the steel plate into a circle, and the material utilization rate is low, so the steel consumption is large. Generally, the steel consumption of the hollow ball joint accounts for about 20% of the entire space frame structure. % to 25%. At the same time, the length of the rod is required to be very precise. In recent years, this kind of joint has been gradually replaced by the bolt ball joint.

2. bolt ball joint

bolt ball joint

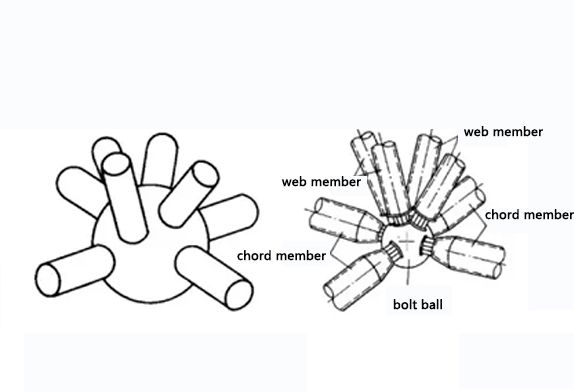

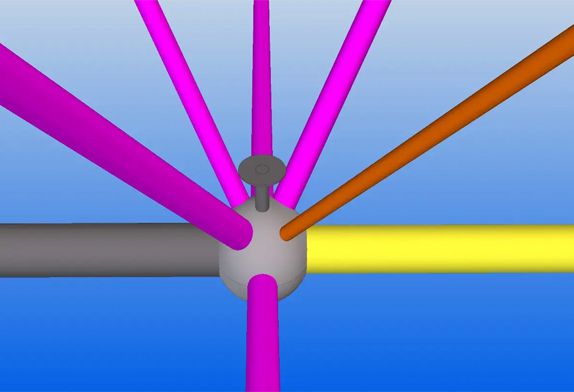

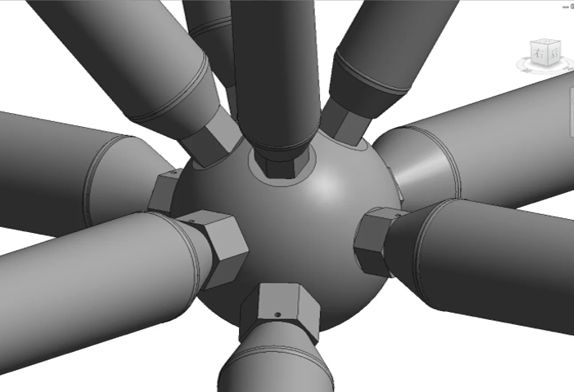

The bolt ball joint is to mill out several square and triangular facets on the surface of a solid cast steel ball. These facets are perpendicular to the radius of the sphere, forming a diamond-like polyhedral sphere. Drill holes on each facet. Hole and buckle, then connect the steel pipe and the sphere with bolts. The bolt ball joint is light in weight and beautiful in shape due to the reduction of the end of the rod. Up to eighteen members can be connected to each node. The welding workload at the nodes is greatly reduced, the installation is extremely convenient, it can be disassembled, and it can even be assembled pole by pole at high altitudes without scaffolding. It can be used for all kinds of space frames, especially for space frames composed of quadrangular pyramids and triangular cones. However, the disadvantage of this kind of joint makes the processing of the sphere complicated and the price is high. At the same time, the end of the steel pipe needs to be opened (for bolts), which is not conducive to rust prevention. It needs to be galvanized inside and outside, and the bolt ball joint is hinged.

About Us

About Us 2022-07-13

2022-07-13