1 project overview

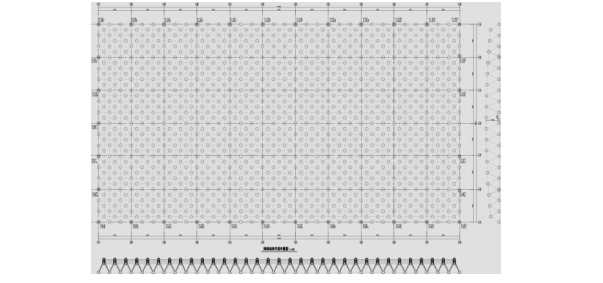

A project plant steel roof space frame for bolted ball node space frame, space frame structure system for double-layer orthogonal conical space frame, axis size of 92.4m × 50.4m, height of 10.6m, the lower chord around support support a total of 33. The total weight of the steel space frame is about 200T.

Steel space frame structure layout

2 Selection of space frame installation method and construction process

2.1 Selection of steel space frame installation construction plan

For the plant steel space frame installation method can be generally divided into aerial loose assembly or ground space frame pre-assembly + overall jacking construction. Considering that the project adopts pre-assembly on the ground, the paint and roof purlins can be inserted into the construction in advance, so the ground space frame pre-assembly + overall jacking is adopted.

2.2 Overview of the overall jacking construction technology of the space frame

During construction, the space frame is assembled at the +0.00m ground and its node projection position. After the completion of the assembly of the space frame, the arrangement of the jacking equipment is finished, and the trial jacking is started, and at least 2 hours are observed to make sure that the shape of the space frame and the rods do not change before the official jacking. After the completion of the space frame jacking, replenish the column top bars, unload the support force, remove the jacking device, the space frame construction is completed.

The overall construction process is as follows:

1、Site preparation work

2、Ground assembly of the completed space frame

3、Elevation point jacking frame installation

4、The whole space frame is jacked up

5、Supporting frame installation

6、Lifting support frame drop frame, demolition frame

2.3 Space frame jacking equipment

The whole space frame jacking system components are hydraulic jack, oil pump station, jacking support frame, computer control system, while multiple jacking point jacking system synchronous operation and through the hydraulic cylinder synchronous control system to achieve multiple jacking point synchronous operation. The overall jacking using 17 sets of jacking points, that is, 50T series of 17 sets, theoretical jacking weight of 850T, the total weight of the jacking space frame is about 200T, far less than the theoretical lifting capacity, the average pressure on the jacking point is less than 12T.

The oil cylinder and hydraulic supply system are produced by professional manufacturers, the single oil cylinder (working cylinder: 160/140-810) lifting force is 50 tons, the hydraulic supply system (XZTDYY) maximum supply pressure 31.5GP, and after several successful linkage tests.

The main material of the jacking frame is Q235B, and the standard section size is 1mx1mx0.77m. The standard section support frame uprights are made of Ø114×7.5 steel pipes, and the webs are made of rectangular pipes 60X60X6.0. Column foot and bearing platform connection:Support frame Ø114×7.5 steel pipe bottom mouth welded Ø170×12 flange, placed directly on the 20X1500X1500 steel plate, the support frame under pressure.

Each jack installed a displacement sensor, computer control system according to the pre-set program to control the jacking, so that the object being jacked up synchronously.

3 Introduction of jacking process

3.1 Jacking working principle

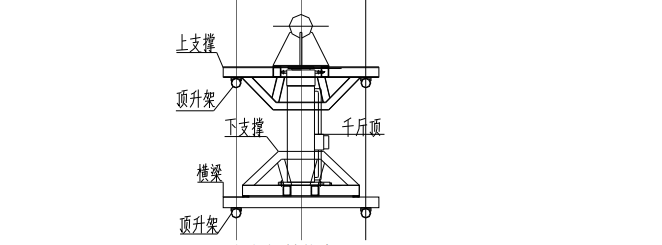

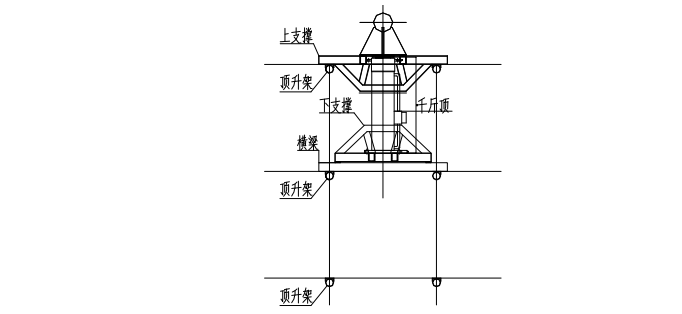

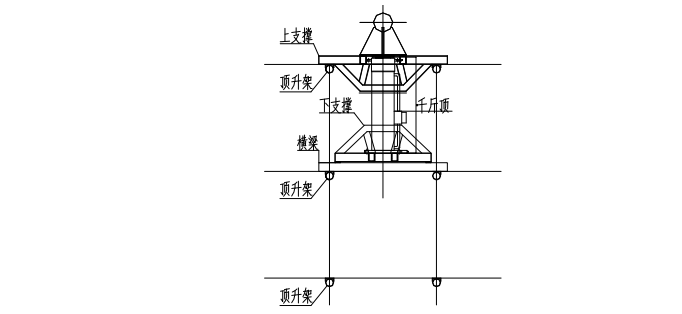

Drawing on the design concept of the tower crane, jacking is the hydraulic jack placed in the bottom position of the support frame, the upper part of the jack and the space frame bolts ball node tight top, jacking construction 770mm after the completion of a jacking, and then install the standard section of the support frame, and then control the jack back down and make the bracket back down to the lower base, jack continue to control back down, take off the jack and jacking pressure plate replacement to the penultimate section of the support frame Standard section, and so on and so forth, until the completion of the overall space frame jacking operations.

3.2 Preparation work before jacking

1) Calibration of the space frame axis, such as position deviation greater than 20mm, must be adjusted before jacking operations.

2) Overall control the height of the bottom of the cylinder homogeneity, deviation shall not exceed 20mm, such as the need to adjust the difference.

3) Test jacking, make all cylinders force has been, and let the space frame jacking to off the ground.

4) Suspend jacking, observe 8 hours whether there is any abnormality in the space frame and foundation, and make adjustment in time.

5) Foundation foundation requirements, must be flat, compacted, foundation bearing capacity shall not be less than 100KN / m.

3.3 jacking process overview

1) Jacking work shall be carried out by professionals.

2) At the beginning of jacking construction, the space frame is jacked up 50mm each time, and can be raised 100mm each time after ensuring consistent rhythm, checking the height of the space frame every 200mm at the beginning, and checking the height of the net frame every 500mm after stabilization to ensure the synchronization of the space frame jacking.

3) After the construction of each shift, the overall inspection will be carried out by a special person to avoid mechanical failure.

4)The diagram of jacking work (one stroke) is as follows:

(a)Initial state

(b)Raise one stroke and install standard section of support frame

(c) The return cylinder of the pump station is raised and the beam is moved up to complete a stroke

3.4 Adjustment of the verticality of the space frame jacking

When the space frame is lifted horizontally, it is controlled by horizontal ties and will not move horizontally; for the adjustment of verticality, the following steps are taken to adjust:

1) Replace the computer operation with manual operation, and read out the pressure of the point to be adjusted, and make a record.

2) Select the point with the largest deviation of verticality as the first adjustment point. Decompression manually until the jacking frame.

The bottom part can be moved until. Move the distance to the actual deviation value plus 5~8mm (pre-lateral) and manually pressurize so that the pressure value is close to the original recorded value.

3)Adjust other points in turn.

4) Adjustment is complete, replace with computer control and continue jacking.

3.5 jacking equipment removal

The specific method is: measure the elevation position of the space frame node before unloading the equipment, then by synchronizing the jacking equipment under the control of the computer to drop 10mm, observe whether the equipment moves uniformly, while measuring the change in the elevation of the space frame node again, until the completion of shedding.

3.6 Support frame augmentation and dismantling

When the support frame is increased, the lower bracket body is stressed, when the rod is fully extended out of the frame body increase the standard section of the support frame, the relevant bolts are tightened and the piston rod is retracted, the upper bracket is stressed, when the piston rod is fully retracted, the lower bracket is collected to the last stressable place, the upper moving crossbar (stressing rod), the crossbar should correspond to the position of the lower bracket stressing beam; when the support frame body is removed, the upper bracket body is in a stressed state, the piston rod is retracted to not stressed, move down the crossbar (stressed rod), the crossbar to correspond with the lower bracket stressed beam position, piston rod out, move the lower bracket to the next support frame, so that the lower bracket is stressed, the upper bracket is not stressed, remove a section of the support frame. It should be noted that when increasing the height, the support frame is increased one section at a time. After removing two sections of the support frame according to the above method, the remaining support frame is lifted flat to the ground with a crane and then removed.

By preassembling the steel space frame on the ground after the overall jacking, it can effectively accelerate the construction progress and construction quality, while reducing the amount of overhead work to ensure construction safety.

About Us

About Us 2023-08-11

2023-08-11