( 4 ) Overall hoisting method. The overall hoisting method mainly refers to a construction method in which the space frame is hoisted into place by a crane after it is assembled on the ground. This construction method is suitable for the installation of various space frame structures, because the connection of the entire space frame unit is not carried out, so that the construction quality can be better guaranteed, but at the same time, higher requirements are put forward for the construction site.

( 5 ) Overall promotion method. The overall lifting method mainly refers to using the frame structure of the construction project as a support, installing small lifting equipment such as flat lifts and hydraulic jacks on the top of the frame structure, and lifting the space frame while carrying out the sliding form of the frame structure. method. This construction method includes different application forms such as individual lifting, net lifting and formwork lifting, beam lifting and net lifting, and sliding form lifting. During the construction period, it can be gradually raised and the height can be accumulated, so it shows certain application advantages in the assembly of high net frames.

( 6 ) Overall jacking method. The overall jacking method mainly refers to a construction method in which the space frame is assembled on the ground at the design space position, and then the space frame is lifted to the design height by a jack. The jack of the overall jacking method is set under the space frame, and the space frame is lifted up to the design elevation. At the same time, the lifting equipment is installed above the space frame. The lifting equipment lifts the candles of the space frame and raises the space frame by raising the lower components. This construction method is similar to the overall lifting method, and is suitable for space frame structures with large spans. In summary, there are various construction methods for the space frame structure of the gymnasium. The application of the specific construction method should be combined with the structure type of the space frame structure of the construction project, and through a comprehensive analysis of factors such as quality, safety, economic benefits, construction progress, and construction technical conditions, to finalize.

- Construction practice of gymnasium roof space framestructure

- Project Overview.

A city gymnasium has a steel structure roof space frame structure. The gymnasium is an above-ground building with two floors in total. The main body of the building is equipped with a mezzanine. In order to ensure the overall firmness of the internal structure of the building, reinforced concrete was introduced during the construction of the gymnasium for structural construction; during the construction of the roof, it was built into a two-way cross steel truss structure, which has good stability. The roof plane of the gymnasium is an eight-slope roof, the roof width is 67.2m×67.2m, the plane length is 69.3m×69.3m, and the surrounding column spacing is 8.4m. During the construction period, trusses with various stiffnesses are used in various parts of the building, and trusses with higher stiffness are applied to the area close to the corner. Under the premise of peripheral support, it shows material saving compared with two-way orthogonal trusses , The advantage of greater rigidity. Combined with the equipment maintenance requirements, the gymnasium roof is equipped with a maintenance horseway in the lower chord plane. According to the characteristics of the roof slope, the horseway is built on the two diagonal slopes of the plane. For the hollow truss, the vertical rods of this part of the truss are connected with the upper and lower chords in the form of rigid connection to ensure the bearing capacity of the truss.

- Engineering features and construction schemes.

During the construction period of the project, the project will be built into a square quadrangular pyramidal bolt ball structure. The main body of the building is supported by the bottom string point, which acts to expand the overall span of the construction project. Combined with the conditions of the construction site and the structural characteristics of the construction project, the space frame structure is mainly constructed by the high-altitude bulk method. During the high-altitude bulk assembly of the space frame structure, there is no need to introduce a tower crane. In the process of assembling the space frame structure, in order to ensure the safe and orderly assembly, a lever and an electric winch are introduced. In terms of construction quality control, the construction of this project focuses on organizing interspersed construction. Combined with the design drawings and construction practice, the 1-axis to 2-axis roof of the gymnasium is set as a concrete structure, and its height is consistent with the height of the embedded parts. link. After the assembly is completed, it will be transferred to the installation area for fixed treatment, and the other space frames will be constructed by the method of ground assembly lever and high-altitude bulk installation by electric hoist. In this way, it is not only necessary to ensure the construction quality, but also to reduce costs and improve construction efficiency.

- Construction steps of roof space frame structure

First, the technical process of roof space frame structure assembly and hoisting. During the assembly of the space frame structure, the construction personnel should first set out the wires, then carry out the acceptance inspection, and then carry out the assembly operation of the lower chord plane space frame of the space frame structure, and then carry out the upper chord to the inverted triangular space frame assembly and the lower chord regular triangular space frame assembly successively, so as to roughly Complete the assembly of the space frame structure. On this basis, it is also necessary to check whether the installation of the space frame structure is qualified or not. If the inspection is satisfactory, the space frame structure can be slid to the assembly position, and then the space frame structure is fixed on the embedded parts, and the space frame structure inspection, The support is welded and finally accepted. Secondly, start space frame assembly. First, check the relevant indicators of the embedded parts such as the axis height and position, and check whether they meet the assembly requirements. During the assembly process, the axis and height of the support of the space frame should be adjusted reasonably, so as to effectively ensure the assembly accuracy. Then hoist the 2-axis to 3-axis space frames to the concrete roof at the 1st to 2nd axis of the building, and then assemble these space frames on the concrete roof in combination with the design drawings.

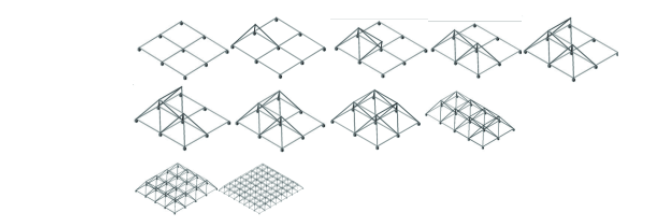

Again, start space frame assembly. Combined with the design drawings, start the space frame splicing first. Before splicing the bolt ball start-span space frame, a fulcrum should be established on the lower string part according to the design drawing. This fulcrum is about 200mm to provide support for the space frame. During the assembly of the space frame, the spiral ball should be assembled in combination with the design drawings. In the area of the lower chord support, square wood fulcrums should be built in advance to provide support for the spiral ball and the lower chord. At the same time, the vertebral body units of the space frame should also be assembled, and then the assembled vertebral body units should be transferred to the design space position. According to the design drawings, the upper chord rods and web rods should be connected to the corresponding positions to establish a stable structure. During the assembly process of the starting span space frame, the corresponding assembly position should be padded with the help of skids, so as to effectively avoid the displacement of the lower string node. In addition, during assembly, each node should be monitored to prevent displacement. Next, a unit space frame assembly is carried out at the position of axis 1~2. After the process is completed, it is slid to the position of axis 2~3, and then the assembled space frame is inspected. After the inspection is satisfactory, corresponding fixing processing is carried out. In addition, it should be combined with the design drawings to adjust the dimensions that do not meet the actual requirements during the assembly of the space frame, and fix the support after the adjustment. The construction process of the space frame structure is shown in Figure 1 .

Figure 1 Schematic diagram of the construction process of space frame structure

Finally, the high-altitude bulk space frame. Slide the starting space frame to the position in the design space, and then check whether it meets the actual requirements. After the inspection is satisfactory, use it as the basis, and then use the lifting equipment to lift the small unit vertebral body to start filling the space frame. After the starting net frame is assembled, the axis of the space frame support is confirmed and adjusted, and the support is temporarily fixed. Other space frames are assembled by the high-altitude bulk method. The assembly process is to assemble the small unit of the space frame triangular pyramid according to the design drawings. After this part of the work is assembled on the ground, it can be slid to the design space position and lifted The equipment moves the small unit cones, and the construction workers carry out the docking and assembly of the high-altitude nodes.

- Construction quality control.

In order to ensure the construction quality, it is necessary to take necessary construction quality control measures. First of all, the quality awareness of management personnel and construction personnel should be enhanced, quality awareness education and business technical training should be increased, the overall quality of all personnel should be improved, and construction quality should be guaranteed based on work quality. Secondly, organize relevant personnel to study the design drawings carefully, and carry out joint review of design drawings to ensure the completeness and scientific feasibility of the construction organization design. Thirdly, the space frame construction should be carried out in accordance with the requirements of relevant specifications. If any problems are found during the construction period, they should be reported to the relevant departments as soon as possible, and they should be dealt with effectively to ensure that the construction quality meets the qualified standards. Then, earnestly carry out the elevation, axis detection and acceptance of the column embedded parts at the construction site. Finally, strictly implement the quality inspection system, carry out various construction records, strictly abide by the construction specifications, and ensure that each process meets the requirements.

space frame structure is a commonly used structural form in the construction of large-span buildings today. The selection of different construction methods has different impacts on the construction management objectives of construction projects. In the construction practice of the gymnasium roof space frame structure, comprehensive consideration should be given to various factors to select the applicable space frame structure construction method to ensure the safe and orderly construction.

About Us

About Us 2023-07-10

2023-07-10