For a long time, the construction industry has been a major steel consumer. In 2020, the steel consumption in the construction industry will reach 574 million tons, with a growth rate of 13.4%, accounting for 58.5% of the annual steel consumption of 981 million tons. More than 95% of the buildings are reinforced concrete or steel structure buildings, and the annual consumption of wire and plate accounts for about 50% of the steel production. Compared with the steel bars in reinforced concrete, the steel recycling rate of beam and column components in steel structure buildings is higher when they are dismantled or rebuilt. Recycling and reuse of steel structure building materials have become an important way of steel utilization in developed countries.

In the past 10 years, China’s steel structure buildings have maintained a rapid growth stage. According to statistics, in 2021, the newly-started prefabricated building area in the country reached 740 million square meters, an increase of 18% compared with 2020, accounting for 24.5% of the newly-built building area. Among them, the newly-started prefabricated concrete structure buildings and steel structure buildings are respectively 490 million square meters and 210 million square meters accounting for 67.7% and 28.8% of the newly started prefabricated buildings respectively. Statistics do not yet include some industrial plants under construction, logistics storage, steel structure bridges, etc. From the perspective of construction steel structure output and output value, the national steel structure output in 2021 is about 85 million tons, with an output value of more than 900 billion yuan, accounting for about 14.1% of construction steel.

To vigorously promote steel structures is not to use a large number of steel structures, but to build more and larger houses with the least amount of steel on the premise of ensuring structural safety, and to take the road of weight reduction and lightweight. Through the use of advanced shock absorption and isolation technology and materials, the amount of steel used in steel structures is controlled within a reasonable and applicable range, and the rational consumption of construction steel is returned to reduce the steel production capacity for the country, reduce carbon emissions from the source, and contribute to green development.

To do a good job in the big article of carbon emission reduction of steel structure buildings, we must start from changing the concept of development and the concept of steel use, and focus on the following four aspects to do a good job.

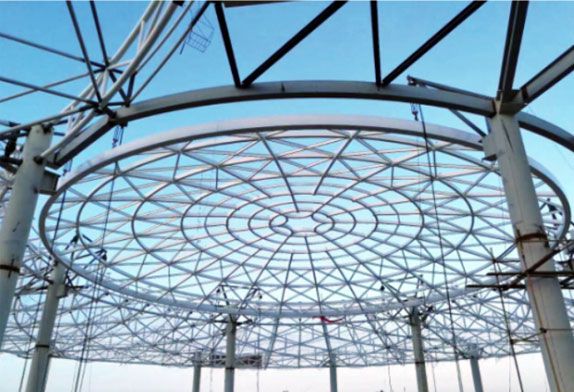

Meilan Airport Phase II Expansion Project—China Steel Structure Gold Award Project

1. Saving steel to achieve carbon reduction

Compared with the steel structure application level of developed countries in the world, there is still a big gap in China in terms of steel concept, steel structure theory, technical system research, and design level. From the perspective of steel structure output, output value and construction in progress, our country is a big country in steel structure, but not a strong country in steel structure. At the 2020 Seminar on the Comparison of Seismic Technology and Specifications of Steel Structures between China and the United States, experts found through comparison that the steel structure design schemes of the same seismic fortification level are applicable to their respective building standards, and the amount of steel used in the United States is only about 2/3 of that in my country. We still have a lot of room for improvement in the optimization of steel structure building schemes, improving the efficiency of steel use, and the level of application.

In terms of analysis, the history of the promotion and application of steel structure buildings in our country is not long, and the current construction management system is not suitable for the development environment of industrialized buildings. The investment in steel structure technology research and development is insufficient, and there are few designers who understand the performance of steel materials. It is customary to use traditional concrete building ideas to promote steel structure buildings, and there is no systematic and holistic thinking on steel structure buildings based on industrialized building manufacturing and professional integration. There are also situations where the design, production and construction of steel structures are out of touch with each other, and the advantages of steel structures have not been fully utilized.

To develop steel structure building vigorously, we must pay attention to improving steel utilization efficiency and reducing steel consumption. The medium thick plate and section steel consumed by steel structures are all industrial raw materials produced by smelting technology and complex process with iron ore as raw materials. The smelting, rolling and production process is also a process of high energy consumption, high emission and high investment. Steel may be sold at “cabbage price”, but it must not be used as “cabbage”. In the use of steel policy guidance, through the concept of green steel is to improve the efficiency of steel application, to ensure safety and meet the function of the premise, do “just right” to use steel structure, reduce waste, do everything possible to reduce the cost of steel structure engineering. From the actual situation of the project, the steel structure of 30 floors and 100 meters high in the same lot, due to the different structural system, the amount of steel used from 75kg/ m2 to 150kg/ m2. If 10,000 square meters of construction with 1000 tons of steel structure can meet the requirements, but not with 1500 tons, it is a waste, and some engineering steel is surprisingly large.

2. Green construction to achieve less carbon

Carbon emissions in the construction phase of steel structure buildings mainly refer to the energy and resource consumption in the engineering construction process and the carbon emissions from the transportation of parts and components. That is, the carbon emissions from the materialization process of buildings are often referred to. Compared with the carbon emissions from the production of building materials and the operation of buildings, the proportion is not very large. However, the carbon emissions of the building materialization process directly affect the social environment and pollute the air, change the dusty and dirty situation of traditional building products, and make the site “clean and tidy, not muddy”, which is the advantage of steel structure building. Through the promotion of green construction technology for steel structures, the use of modern information technology and engineering software, and three-dimensional simulation of the steel structure construction process, to achieve fine production, production, accurate installation in place, solve the problem of construction professional coordination and system integration, can reduce the carbon emissions of the construction site.

At present, there is still a large room for improvement of steel structure construction level in our country, and there is a gap with the on-site management scene that industrial buildings should have. The construction enterprises that undertake steel structure engineering do not understand the professional characteristics of steel structure, and most subcontract the project to some professional enterprises with lower qualifications of steel structure, driving down the price and resulting in the low production management level of some enterprises. Insufficient investment in technology and production equipment and personnel. Some engineering structures are complex, production and construction are difficult, many processes, and professional coordination is difficult, and the green construction level of steel structure is not high. To promote the green construction of steel structure engineering, enterprises take the quality and management objectives of the construction period as the starting point, according to the overall systematic thinking of industrial buildings, and carry out the integrated design and construction of the whole professional and process of steel structure construction. Professionals should be organized to deepen and optimize the construction drawings of steel structure, and structural engineers, designers, and builders should be organized to communicate with the platform. Focus on optimizing the size and specifications of the structure section to make it suitable for production, transportation and installation, and improve the building effect and construction efficiency. Optimize the construction technology and installation mode of the structure to save construction time. Optimize the section form of the component to reduce the processing cost. Optimize the connection mode of structural nodes, reduce complex nodes, improve the stability of the building structure, and provide convenience for the next process.

Green construction is in accordance with the requirements of green development, through scientific management and technological innovation, to save resources, protect the environment, reduce emissions, improve efficiency, and ensure the quality of construction. And it adheres to the integration of planning, design, construction, and delivery of the whole process, according to the requirements of green, information, intensification and industrialization, scientific planning and rational allocation of resources for construction organization, preparation of targeted steel structure special construction program, take effective management measures to reduce repeated construction. And it selects advanced and applicable installation methods, formulates reasonable installation processes, reduces on-site formwork and scaffolding construction, achieves accurate cutting material, and fine management, and reduces the loss rate of building materials. The application of an intelligent management platform to monitor the energy consumption of key links and energy consumption equipment can reduce the resource consumption of the construction process.

3. Green building materials to achieve low carbon

The steel structure is only the skeleton of the building, and the structure must be “dressed and capped” to realize the building’s function. The new green enclosure wall plate is the perfect match for the steel structure. The “three plates” of steel structure building is one of the bottleneck problems that perplex the promotion of steel structure. The price of a good envelope plate is high, and the quality and durability of the plate at a low price can not be guaranteed. However, the application of the enclosed wall plate is one of the advantages of the steel structure building system, the higher the degree of site assembly, the more can reduce the consumption of water, electricity, sand, and stone in the site construction, from the extensive management of the site to the refined management, so, for the steel structure to find suitable floor and internal and external wall plate, relying on the design, production and construction integration system integration, Relying on the industrial chain of section steel, building materials, and supporting parts to cooperate with each other, it is very important to improve the proportion of green building materials used in steel structure buildings.

The use of different materials for lightweight wall panels, the effect of reducing carbon emissions is completely different. The choice of advanced and appropriate assembly technology and method, and the use of green building materials in the process of carbon emission reduction level have different effects. According to the data of the Metallurgical Industry Planning and Research Institute, the carbon emission of steel structure building in the whole life cycle is 261.8kg/ square meter, and the carbon emission of the casted reinforced concrete building is 317.5kg/ square meter. Compared with the carbon emission of steel structure buildings, the carbon emission of steel structure buildings is 17.5% lower. Although there are differences in the research data of some well-known scientific research institutions in China, it is an industry consensus that steel structure buildings are excellent students in carbon emission reduction, with potential to be explored and articles to be done. If the steel structure building is integrated and effectively combined with new energy products and photovoltaic industry systems, and the passive integrated housing is promoted, its effect of energy saving and emission reduction, green and low carbon will be more obvious.

Solving the green building materials and connection sealing materials and technical process of steel structure matching is the focus of scientific research on steel structure building application, and is also key to ensuring the quality stability, and durability of steel structure building service life. It is necessary to optimize various green building materials with high strength, high performance, high durability, corrosion resistance, and anti-aging, so as to prolong the service life of buildings and reduce the frequency of component replacement. In the long run, reducing the consumption of raw materials, achieving source emission reduction, and improving the energy-saving standards of building envelope materials is the development direction of steel structure buildings in the future.

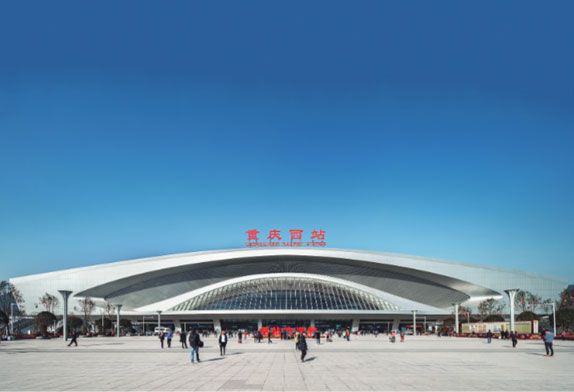

Chongqingxi Railway Station —China Steel Structure Gold Award Project

4. Scrap recycling to achieve carbon reduction

To improve the proportion of steel structure building materials recycling, we must first from the design end hand, in the structural design selection, and construction technology, considering the building function and future service life, and adopt a structural system suitable for demolition and recycling. For steel structure housing, it is necessary to increase the proportion of section steel components, and steel mills directly produce section steel components for steel structure buildings. In this regard, in Japan’s multi-story and small high-rise steel structure housing, the use of cold forming beam through steel structure technology system is worth learning, the load-bearing column is not pouring concrete, bolt welding connection technology is reliable, the degree of on-site assembly is high, reduce steel structure again production processing, manufacturing link energy consumption and emissions, promote the industrial upgrading of steel enterprises.

We will attach importance to the recycling of steel from the demolition and reconstruction of old steel structure buildings, and introduce relevant policies to encourage and support measures to improve the utilization rate of scrap steel recycling. According to the relevant research data, the carbon reduction effect of steel scrap recycling and reflow is obvious. According to the current blast furnace process standards, carbon dioxide emissions of iron ore steel making, carbon emissions of 1 ton of crude steel is 1700~1800kg. Carbon emissions of each ton of crude steel are only 700~800kg when scrap steel is recycled back, and the production process and process chain are greatly shortened. To improve the steel material standards, steel design specifications, rational use of weathering steel, and high-strength steel, to reduce the use of steel, and promote the engineering field of carbon emission reduction work.

Recycling waste steel for reuse meets the requirements of green development in the whole life cycle of production factors. According to the calculation comparison, the steel recovery rate of super high-rise steel structure buildings is more than 65%, the steel recovery rate of schools, hospitals, and other steel structures is more than 70%, the steel recovery rate of high-speed railway stations houses, exhibition centers, cultural and sports venues is more than 80%, the steel recovery rate of industrial plants and large-span logistics storage facilities is more than 90%, and the steel recovery rate of urban municipal bridge steel structure is more than 90%. The rate is above 95%. Scrap steel recycling, instead of iron ore import dependence, its economic value, the value of national strategic material reserves is a political account.

At present, the general view of society and the market on steel structure building is that the cost is high, the matching is not strong, and the advantage of “light and economical ” is not reflected. In particular, the design of steel structure is conservative, lacking the development concept of “reduction, reuse and circulation”. As the main stadium of the Olympic Games, the “Bird’s Nest” in Beijing uses 80,000 tons of steel, while the “London Bowl” in London uses 21,000 tons of steel. Considering the different earthquake protection needs of the two places, the steel amount can be greatly saved if the plan is reasonable. It is an indescribable fact that some famous steel structure buildings in our country pursue “strange” shapes, has complex structures, and use too much steel. The concept of circular economy in the UK is also worth learning. For example, the design of “London Bowl” is divided into two floors, the bottom floor is the permanent stadium site, and the top floor is completely dismantled and recycled after the game, and even the seats are all sold.

About Us

About Us 2023-03-15

2023-03-15