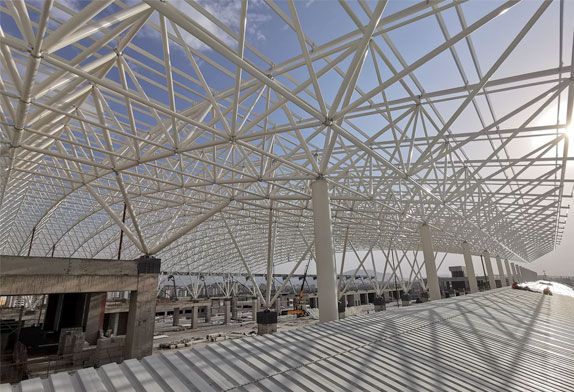

Fireproof coatings for space frame processing engineering have remarkable fireproof, heat insulation, heat preservation, water vapor, corrosion resistance, and other characteristics. It is generally applicable to the fire protection maintenance of steel frame structures of indoor and outdoor engineering buildings and buildings with a fire prevention time of ≤2.5 hours. To prevent fire in the early stage and alleviate the expansion of the fire, the fireproof coating for space frame processing engineering is a new type of fireproof coating developed by adopting new technology. It is characterized by the formation of a balanced and high-density sponge-like foam insulation layer upon seeing the fire. It is of great significance to ensure the safety of the nation and people’s lives, especially for the protection of exposed steel structures in stadiums and factories. Uses: Fireproof coatings for space frame processing engineering are mainly used for fireproof protection of steel frame structures and steel products in industrial and industrial buildings that are relatively destructive by fire.

Fireproof coatings for space frame processing engineering have remarkable fireproof, heat insulation, heat preservation, water vapor, corrosion resistance, and other characteristics. It is generally applicable to the fire protection maintenance of steel frame structures of indoor and outdoor engineering buildings and buildings with a fire prevention time of ≤2.5 hours. To prevent fire in the early stage and alleviate the expansion of the fire, the fireproof coating for space frame processing engineering is a new type of fireproof coating developed by adopting new technology. It is characterized by the formation of a balanced and high-density sponge-like foam insulation layer upon seeing the fire. It is of great significance to ensure the safety of the nation and people’s lives, especially for the protection of exposed steel structures in stadiums and factories. Uses: Fireproof coatings for space frame processing engineering are mainly used for fireproof protection of steel frame structures and steel products in industrial and industrial buildings that are relatively destructive by fire.

space frame engineering processing requirements

1. Detailed information solution of fireproof coating for space frame processing engineering:

After shot blasting and derusting to reach the SA2.5 limit, the details of the steel plate coated with fireproof coating for the steel frame structure should be strictly dewatered and antirust. Hand-made anti-rust treatment to achieve st3 level and above. The detailed information after the anti-rust treatment is treated with alkyd red lead or epoxy anti-rust paint.

2. Construction method

Low-voltage airless sprayers can also be used. Following the importance of fire resistance grade, painting again after one layer is finished, can be used in roll coating or paint. After the first layer of coating is dry, apply the first layer and the second layer. When controlling this architectural coating, it is necessary to control the fireproof closed paint, so as to avoid the damage of the fireproof coating to the natural environment of precipitation and high ambient humidity. The consumption is 0.25kg/m2. During the coating construction process, the air humidity is lower than 85%.

3 Coats

Coating thickness: The wet film thickness of each fireproof paint coating should be ≤250um.

Coating interval: dry (not sticky to touch)

Diluent cleaning: 2001 special diluent cleaner.

Or organize litigation by the Commodity Trustees. If it still does not meet the requirements of this standard, the division of project acceptance stipulates that if the fire protection coating enterprise of the control network frame processing project finds that the quality of the new product does not meet the requirements of this standard, two people will jointly review it. The controlling enterprise has the right to return and exchange goods.

Labeling, transportation, outer packaging, storage: Unused paint packaging should be re-sealed tightly to prevent dryness and easy replacement. It is suitable for this standard and under the transportation and storage conditions. The storage period is one year from the date of production of the product. . The surface of each can of new products should have labels, declarations, commodity titles, production dates, production company titles, addresses, and production and manufacturing dates. Packed in a sealed iron box, each can weigh 20kg, and stored in a cool, naturally ventilated place. When transporting materials, avoid rain, sun exposure, and moisture intrusion, and pay attention to airtightness.

About Us

About Us 2023-04-26

2023-04-26