During the actual installation of steel structures, it is often encountered that connections such as sub-trusses in the longitudinal direction of the building and auxiliary trusses of crane beams will be troublesome to install on-site due to the difficulty in controlling the longitudinal dimensions. This involves the enlargement of the bolt aperture of this part of the member, and the difference between the bolt aperture and the screw should be limited to how large a range is appropriate? Strict limitation of the diameter difference is good for the quality of the structure, however, too small a diameter difference will bring trouble to the construction.

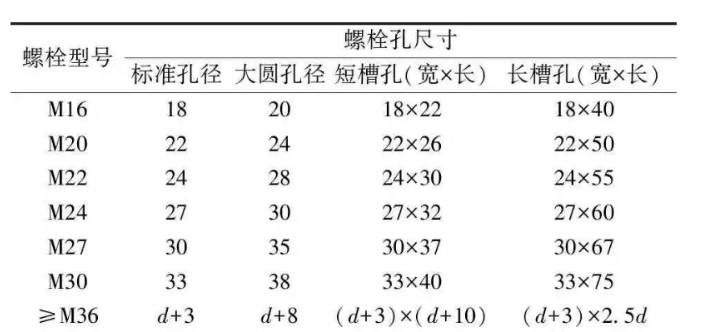

The specification stipulates that the diameter difference of friction type high strength bolts is 1.5~2mm, to facilitate the smooth installation on site, sometimes it is necessary to enlarge or lengthen the hole diameter. And enlargement and lengthening is not arbitrary, need to enlarge and lengthen the performance of high-strength bolts after the impact of research.

In this regard, the Americans have long done experiments. Found that the biggest impact of the Department of the reduction of the connection of the value of the pre-tensioning force, due to the contact surface becoming small and the compression deformation of the plate being large, the friction surface of the anti-slip coefficient decreases as well as increase the sliding and so on.

Recommended “U.S. Steel Structure Design Code” AISC in the “friction type bolt connection in the use of expanding the hole” content, to facilitate the practical application of the project both standardized operation and quality assurance.

About Us

About Us 2024-02-23

2024-02-23