一、Space Frame

1.1 What is a space frame?

A space frame or space structure is a truss-like, lightweight rigid structure constructed from interlocking struts in a geometric pattern. Space frames can be used to span large areas with few interior supports. Like the truss, a space frame is strong because of the inherent rigidity of the triangle. Flexing loads (bending moments) are transmitted as tension and compression loads along the length of each strut.

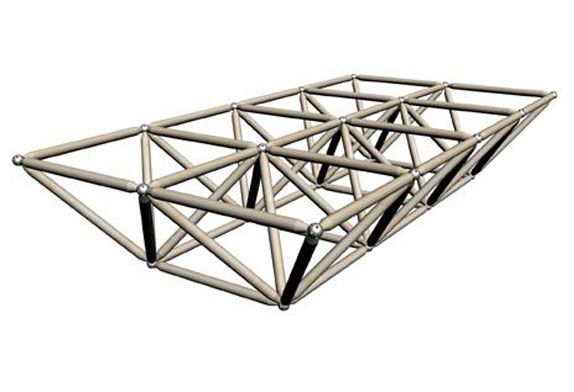

Figure1 space frame structure

Space Frames can span large spatial areas without intermediate columns, by interlocking struts in a geometric pattern, The space frame is a kind of space frame structure, which belongs to the flat plate type; the corresponding space structure is the curved surface type, which is called the reticulated shell.

First of all, the rigidity of the space frame is large. In order to ensure this, it is usually designed to have two layers, and it can be three layers when there are special requirements.

Secondly, the integrity is good, and multiple rods are regularly combined and connected in two or more directions.

With a complete, flexible layout, a unique connection forms its special load-bearing structure。

Which is extremely useful in projects like bulk storage sheds, Sports Stadiums, Airports Building, Shopping Malls, aircraft hangars, hall roofing, etc. It can also form architectural marvels in long Skywalks, and Pedestrian Bridges, and can add aesthetic, rigidity, and long life to smaller span structures like Metro Railway Stations, Swimming Pool covers Toll Gates Canopy, Border Security Gates, and Petrol / Gas Stations.

1.2 Selection of space frame structure

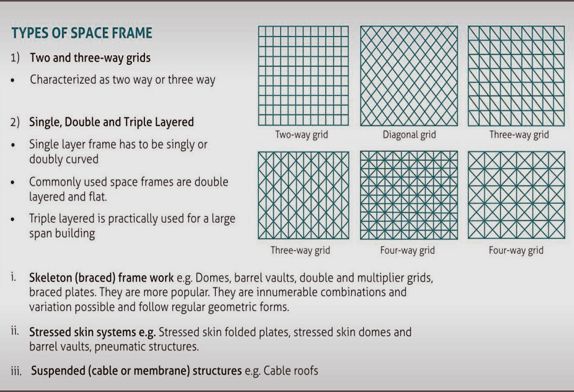

The types of space frames are divided into three categories:

1) Cross truss system: There are common two-way orthogonal placement, two-way orthogonal oblique placement, two-way oblique placement, and three-way, one-way broken line.

2) Quadrangular pyramid system: Commonly there are positive quadrangular pyramids, positive evacuated quadrangular pyramids, checkerboard quadrangular pyramids, oblique quadrangular pyramids, and star-shaped quadrangular pyramids.

3) Triangular pyramid system: there are common triangular pyramids, evacuated triangular pyramids, and honeycomb-shaped triangular pyramids. The support of the space frame generally has the form of peripheral support, point support, or three-sided or two-sided support.

The selection of the space frame is mainly determined according to the comprehensive analysis of the project plane shape, size, roof load and structure, and material supply. Figure 1 and Table 1 show the suitable types of space frames under various support conditions and plane shapes.

Figure2 Types of space frames

Table 1 Space frame structure selection

| Support method | flat shape | Aspect ratio | Space frame form |

| surrounding supporting | rectangle | L/B<1.5 | Positive quadrangular pyramid, oblique quadrangular pyramid, checkerboard quadrangular pyramid, positive evacuated quadrangular pyramid, two-way orthogonal positive placement, two-way orthogonal oblique placement |

| 1.5 < L/B <2 | Two-way orthogonal positive release, positive release quadrangular pyramid, positive release evacuation quadrangular pyramid | ||

| L/B>2 | One-way polyline | ||

| round, regular hexagon, close to a regular hexagon | —— | Three-way, triangular cone, evacuation triangular cone | |

| multi-point support | rectangle | —— | Positive release quadrangular pyramid, positive release evacuation quadrangular pyramid, two-way orthogonal positive release |

1.3 Material selection for space frame structure

Most of the space frame structures are made of steel, mainly Q235B steel or Q355 steel. Generally, the space truss structure can be made of Q235B grade steel.

Q345 steel is mainly used in the large-span space truss structure.

The welding ball, sealing plate, and cone head can also be made of Q235B grade steel or Q355B steel, and the steel number should be the same as that of the rod;

40Cr steel is better for high-strength bolts;

Bolt balls should be made of 45-gauge steel.

1.4 specific application of space frame structure engineering

♦The A380 prefab hangar of Capital Airport is located on the north side of Terminal 3 Capital Airport. It consists of the hangar hall and the annex. The hangar hall has a span of 2m*176.3m and a depth of 110m.

The steel roof of the Capital Airport A380 hangar is composed of a roof space frame structure and gate truss. The roof elevation is +39.800m. The roof structure adopts a three-layer inclined quadrangular pyramid steel space frame, supported by the lower chord, the space frame size is 6.0 m × 6.0 m, and the height is 8.0 m. The roof at the gate adopts welded box-section steel trusses. Most of the space frame nodes are welded hollow sphere nodes. A small number of nodes use the main pipe through welded hollow sphere nodes according to the force requirements. The welded box-section trusses at the gate truss use welded nodes. Steel nodes. The roof support adopts universal anti-seismic spherical hinge support. The space frame members are made of round steel pipes, the gate truss members are all-welded box-shaped, and the space frame structure is supported by the gate truss.

♦Phoenix Mountain Sports Center includes a 60,000-seat professional football field and an 18,000-seat comprehensive gymnasium. The roof plane of the sports hall gymnasium is oval, with the longest middle of about 183m, the widest of about 153m, and a cantilever length of 19~ 24m, and the maximum thickness of the network frame is about 10m. According to the building shape and the hanging requirements of competition performances, combined with the structural force characteristics, the steel structure of the roof adopts a square pyramid space frame structure

二.Pipe truss structure

2.1 What is a truss structure?

The pipe truss structure, also known as the steel structure truss structure or the pipe truss structure, has become a widely used large-span space structure.

First of all, the structure uses thin-walled steel pipes as rods, which are combined in a certain way to form a three-dimensional structure, which can ensure the overall lightweight and flexible layout of the structure.

On the other hand, it can also make it have a good economy. Secondly, the truss structure is connected by welding through the nodes, which does not require connecting parts, and the construction is simpler and more convenient.

Finally, the trusses are closed and connected by circular tubes, which have good fluidity, reduce the influence of wind disturbance on the overall structure, and are not easily corroded inside, which prolongs the service life of the rods.

Figure1 pipe truss structure

2.2 Specific application of pipe truss structure engineering

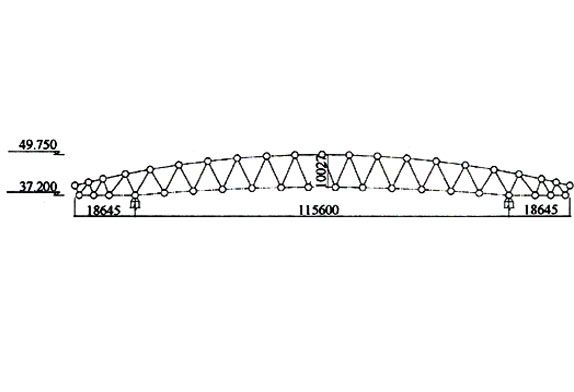

The Shanghai Grand Theater is located on the northwest side of People’s Square in the center of Shanghai. The top of the Grand Theater is a crescent-shaped reverse-arch steel roof, with two floors and three floors in part, with a total area of about 22,000mZ (including the roof’s technical layer). The vertical length is 100.4m, the horizontal width is 94m, the vertical cantilever is 26m, the horizontal cantilever is 30.9m, the radius of the reverse arch arc is R=93m, and the arch height is 11.5m.

The roof system adopts a cross-rigid steel truss structure. There are two main trusses and two secondary trusses in the longitudinal direction. Under each main truss, three thin-walled columns formed by the wall of the elevator shaft are set up. As the supports of the entire roof truss structure, the secondary trusses only play a role in ensuring the integrity of the roof. .

The crescent-shaped roof truss adopts the roof truss without inclined webs, which can not only meet the requirements of the building for the longitudinal traffic inside the steel roof, but also reduce the total number of rods and the joint structure is simple. It has good mechanical performance, great torsional stiffness and bidirectional bending stiffness, and the overall stability of the wall can save a lot of support.

三.Comparison of pipe truss structure and space frame structure

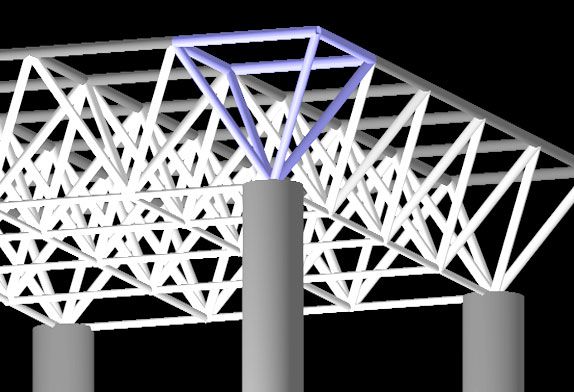

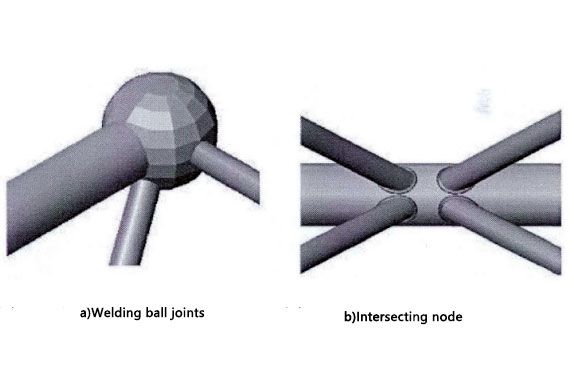

The biggest difference between the space frame and the pipe space truss is the connection method, which is manifested in the different connecting nodes.

The space frame structure generally uses bolt balls or hollow balls as connecting nodes, and additional connecting components are required;

Different from the space frame, most of the space truss structures use intersecting nodes (see the figure below). The intersecting lines are reserved on the main pipe in advance, and then the connecting rods are connected to the main pipe by welding, and the main pipe is connected to the main pipe. The premise is that the two are on the same axis. It should be noted that the welding operation needs to meet the process and its accuracy requirements.

Schematic diagram of connecting nodes of two spatial structures

In addition, considering the connection method of the space truss, it is more flexible in layout and has advantages in terms of modeling diversification.

A comparative analysis of the two is carried out from the perspective of steel structure cost. Since there are many factors to be considered, and different factors are included, different analysis results may be obtained. Therefore, it is mainly considered from the amount of steel used in the structure. Based on factors such as construction and maintenance, the following conclusions are drawn: when the length and width of the building are very different, the space truss structure is more suitable; when the design size of the building is close to a square or a circle, the space frame should be used to balance the external force.

From the analysis of the engineering technology of the two structures, the main differences are as follows:

a) The force of the space frame structure is relatively balanced, while the pipe truss structure mainly bears the external force between the upper and lower layers;

b) The space frame has greater rigidity;

3) Considering that the space truss needs to use intersecting nodes, the reservation of intersecting lines and the welding of rods improve the accuracy requirements, but also increase the workload, and extend the construction time accordingly.

As a professional manufacturer of space truss and tube truss in China, we can provide you with the design, manufacture, and installation of steel structure projects. Welcome to consult us!: marketing01@cnxzlf.com

About Us

About Us 2021-05-11

2021-05-11