In order to generate electricity safely, thermal power plants generally need to store a certain amount of coal in the plant and set up a mechanized coal storage yard. The proportion of traditional coal yards in thermal power plants is about 10% to 15%. With the development of thermal power plants with high parameters and large capacity, the coal storage capacity of power plants is required to be larger and larger. How to improve the utilization rate of the site, reduce the floor space, reduce the amount of earth and stone, and improve the coal storage capacity of the coal yard and the automation level of the operation are the key issues to be solved in the development of the coal storage yard of modern thermal power plants in China. At the same time, with the increasing awareness of environmental protection and environmental protection requirements, large-scale modern coal storage yards also need to solve the problem of pollution in the surrounding environment.

The choice of coal storage form in thermal power plants should be comprehensively determined according to site conditions, coal storage requirements, coal characteristics, and environmental conditions. The coal storage forms used in domestic thermal power plants include open-air strip coal yards, fully enclosed strip coal yards, fully enclosed circular coal storage yards, cylindrical bunkers, and spherical thin-shell concrete coal storage bunkers.

At present, most thermal power plants mainly adopt the layout of barrel coal yards. With the expansion of production scale and the continuous improvement of energy saving and environmental protection requirements, dome-closed coal yards and spherical thin-shell concrete coal storage bunkers are characterized by their high degree of automation, high operating efficiency, low operating costs, good environmental performance, and simple equipment. , get more and more applications and promotions.

Barrel coal yard is a common form of coal storage in my country’s large-scale power plants, coal preparation plants, chemical plants, and other industries. It can maximize the use of site resources according to topographic conditions to achieve as much coal storage as possible. It is currently a common coal storage yard. layout type. The layout of the strip coal yard mainly includes a cantilever bucket wheel stacker and reclaimer, portal roller stacker and reclaimer, and side stacker bridge stacker and reclaimer. These forms are safe and reliable in operation and are widely used in coal storage yards in electric power, coal, and other industries. The strip coal yard has a large amount of coal, which can meet the safe and continuous operation of the unit when the coal supply is tight; the structural facilities are all on the ground, and the structural design is relatively simple; the comprehensive cost of equipment and structure is low. At present, the country’s environmental protection requirements for thermal power plants are getting higher and higher. In order to suppress the flying of coal dust, the coal storage yards of power plants around cities need to be fully enclosed. At present, there are two types of closure of strip coal yards. One is to set up a dust suppression net with a special structure around the coal storage yard, and the top of the coal yard is an open structure. When the wind passes through the coal yard area, the special structure of the dust suppression net minimizes the wind speed, thereby reducing the flying of coal dust caused by the change of meteorological conditions in the coal yard. The investment in this closed form is small, but it is not a fully closed structure and cannot meet the environmental protection requirements of power plants around the city. The second type is a fully enclosed strip coal yard. Along the length of the coal yard, an arch-shell steel structure space frame is set across the entire coal yard, and color steel plates are attached to the space frame. Electric rolling shutter doors are set at both ends of the coal yard to facilitate vehicles or coal pushers entering and leaving the coal yard. A fully enclosed coal yard has outstanding environmental protection performance and is used in areas with high environmental protection requirements; a semi-enclosed coal yard is used in areas where environmental protection requirements are not too high, and the investment is relatively low.

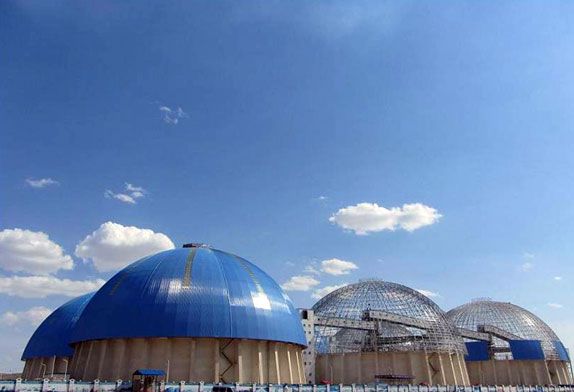

The dome coal yard storage has been used in large thermal power plants in recent years and is a relatively new type of coal yard layout. In the early stage of the introduction of this technology, due to the use of imported equipment and complex civil structures, the investment in circular coal storage facilities was very high. With the digestion and absorption of new technologies, the design of civil structures has been further optimized, and the current investment in circular coal yards has been reduced. The circular coal yard facility consists of a circular coal yard stacker and reclaimer and related auxiliary facilities. The main components of the stacker-reclaimer are the central column, stacker, reclaimer, activation feeder, electrical and control equipment, etc. The unit area of the circular coal yard is relatively small, and the utilization rate of the site is high; the reclaimer looks down along the coal pile surface and rotates to take coal, which can basically remove the coal in the coal yard, and the amount of auxiliary work is relatively small; The field stacker and reclaimer work independently, and the stacker and reclaimer do not affect each other during maintenance, and the equipment is relatively safe and reliable; the design of concrete retaining walls is relatively difficult. Structural calculations are relatively complex. The circular coal yard has two forms: open-air and fully enclosed. The circular coal yard occupies a small area, with large coal storage per unit area, a high degree of automation, and safe and reliable operation. The open-air circular coal yard saves investment and is convenient to deal with spontaneous combustion, but it causes great environmental pollution, while the fully enclosed circular coal yard has the characteristics of strong resistance to severe weather, less environmental pollution, and good landscape effect. Has outstanding advantages.

In recent years, the use of to achieve precise coal blending technology has developed rapidly in my country, which further promotes the application of silos in coal storage and transportation systems. Different from other industries, thermal power plants have many types of coal involved in the coal blending systems due to the requirements on coal quality, moisture, volatile content, etc. Volatile coal type, precise coal blending technology is to blend several different types of coals with different properties into mixed coals according to a certain proportion. Balanced, and easy to fully burn coal, improve coal utilization efficiency, achieve the purpose of saving coal consumption, and reducing pollutant emissions. However, there are many problems and safety hazards in the application process, such as coal agglomeration in the silo, arching, blockage of the silo discharge opening, limited capacity of the silo, spontaneous combustion of coal in the silo, etc. The high investment in silo civil construction makes the application of silos limited in large power plants.

In addition, the hemispherical coal storage bunker is also a closed spherical coal yard widely used abroad. The civil structure of the hemispherical coal storage bunker mainly includes a ring base, an inflatable airbag as an outer membrane, pouring polyurethane, building a reinforced structure, and shotcrete. This kind of civil structure is not yet mastered in China, the cost of technology introduction and cooperation is as high as 1.7 million US dollars per block, and there is no independent intellectual property rights.

According to the above description, it can be seen that the advantages of the barrel coal yard are that the coal storage yard has strong extensibility, wide adaptability of coal types can turn coal for high volatile coal types, simple equipment and easy maintenance, and relatively flexible operation, but it takes up less space. The land area is relatively large. When fully enclosed, it can also meet the environmental protection requirements of urban power plants. The advantages of the circular fully enclosed coal yard are that the coal storage is large and the appearance is beautiful under the premise that the unit occupies a relatively small area. The disadvantage is that the mechanical equipment of the circular coal yard is relatively complex and the maintenance workload is large. The cylindrical silo has a small amount of coal storage and a high cost. It is suitable for coal “spontaneous combustion” when used as a storage silo, and the hidden dangers of coal agglomeration, arching or clogging of the silo mouth in the silo are difficult to completely eliminate, which is a huge hidden danger to safe production. However, since the silo can realize precise coal blending, it is the correct choice to use the silo as a link in the coal storage, transportation, and production process – the use of a process silo, but as a large thermal power plant, the cost-effectiveness of using a silo to store coal is low. . Therefore, in the case of comprehensive land occupation, a fully enclosed circular coal yard should be adopted; if there are requirements for equipment configuration, extension and expansion conditions, and comprehensive cost reduction at the same time, the fully enclosed strip coal yard scheme should be recommended; For power plants with high requirements for coal blending and a small amount of coal storage or in the case of a backup coal yard, the silo arrangement is recommended.

This paper analyzes and summarizes several common coal storage systems in thermal power plants. The selection of coal storage methods needs to be comprehensively considered according to the area of the plant area, local environmental impact assessment reports, and cost indicators. Due to the increasingly high requirements for environmental protection in my country and the world in recent years, closed coal yards will be widely used as the main coal storage method.

About Us

About Us 2022-11-21

2022-11-21