1 Project Introduction

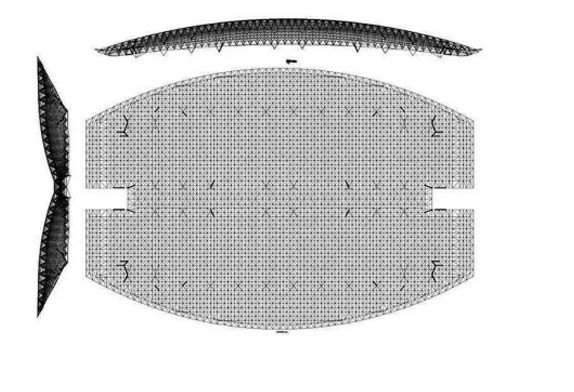

The main body of the airport terminal is a reinforced concrete frame structure, and the roof structure adopts a welded spherical curved space frame roof. The projected area of the space frame is 7706.2m², the maximum span is 18.0m, and the maximum span of the cantilever end is 12.0m. The height of the highest point of the space frame is 16.050m, and the height of the lowest point is 6.685m. The overall shape of the space frame roof structure is similar to the flapping wings of a butterfly, and the roof extending on both sides is like the giant wings of a butterfly (see Figure 1\2).

Figure 1 Airport Steel Roof

Figure 2 Airport Construction Roof

2 space frame roof installation scheme

2.1 Introduction of space frame roof partition

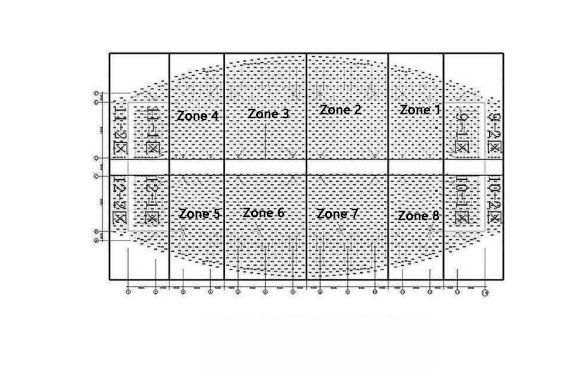

The total weight of the space frame roof of this project is about 239.07t, and the projected area of the space frame is about 7706.2m. According to the distribution of frame structure columns and frame beams and the query results of lifting and hoisting resources in Xinjiang, the space frame roof is divided into 12 areas, of which the single weight of the space frame is 32.32kg/m2, and the maximum area of the space frame is 799.2m, weighs 25.83t, the minimum partition space frame area is 168.6m, and weighs 5.45t (see Figure 2).

Figure 2 space frame roof zoning

Figure 2 space frame roof zoning

The space frame roof hoisting sequence of this project is as follows: Area 9-1 → Area 10-1 → Area 1 → Area 8 → Area 2 → Area 7 → Area 3 → Area 6 → Area 4 → Area 5 → Area 11-1 → 12 -1 area, the space frame assembly sequence is the same as the hoisting sequence, and the hoisting does not affect the normal construction of the assembly. After the ground assembly and hoisting construction of the space frame is completed, the operation frame is erected, and the scattered installation of the 9-2 area, 10-2 area, 11-2 area, 12-2 area, and the high-altitude closing part is carried out.

Areas 1 to 8 plan to use four 50t truck-mounted cranes for space frame lifting and hoisting, and areas 9-1, 10-1, 11-1, and 12-1 plan to use two 50t truck cranes for space frame lifting and hoisting.

2.3 space frame ground assembly

Figure 1 Airport terminal building

When the airport building space frame is assembled by partition, it is advisable to stagger the supports and offset them in parallel. The partition space frame is assembled at the A1 position 3000mm away from the concrete column as a whole. When the partition space frame is assembled, the truck crane lifts the partition space frame beyond the support by 200mm. After the space frame is stabilized, multiple truck cranes rotate the boom synchronously. Move the partition space frame to the concrete support position A, and then perform a series of procedures such as hole, calibration, and fixation.

About Us

About Us 2023-02-20

2023-02-20